TE100 Thermal Resistivity Test System for Metallized Substrates, TIM, and Chip Bonding

Overcome thermal challenges in next-generation power modules with actual thermal data for metalized substrates in operating conditions.

Compare thermal resistance (K/W) between different metalized substrates and geometries, and collect data for effective semiconductor lifecycle management.

| : TE100 |

Evaluates the Thermal Properties of Power Semiconductor Substrates and Materials in 30 seconds

Want to increase your semiconductor yield?

Chip fabs are now putting multiple die together from different technologies, sometimes from different foundries. And even within a single foundry, every die stack is unique.

If you’re working in R&D, you know the struggle is real in managing thermal runaway or accelerated aging in next-generation power devices.

That is a loss of yield for those who are managing deployment.

The first and only analyzer for accurate thermal resistance data of metallized substrates in real workload

- Measure actual thermal data for metallized substrate in operating conditions

- Compare thermal resistance (K/W) between different metallized substrates and geometries

- Collect data for effective semiconductor lifecycle management

Test, don’t guess your thermal data

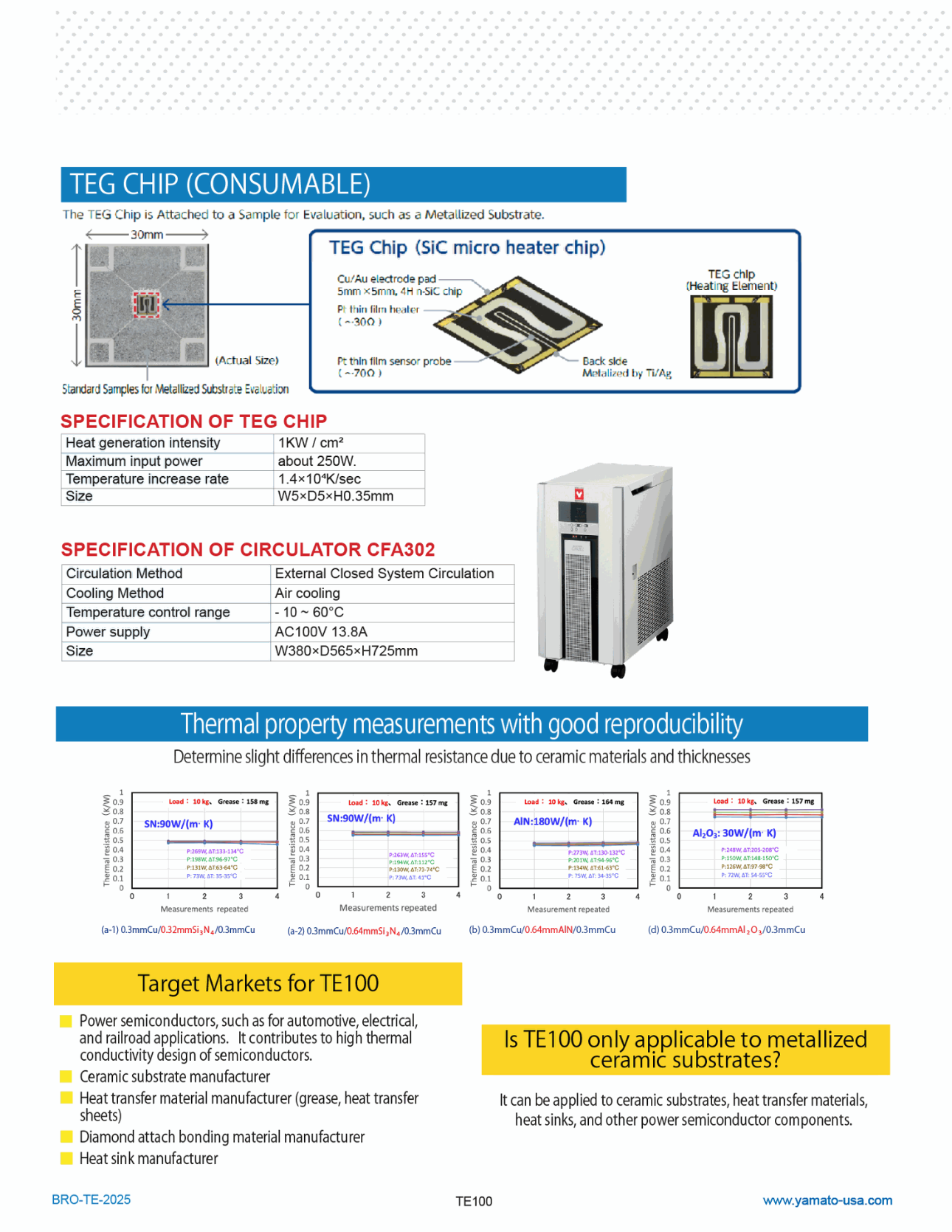

The ISO4825-1:2023 Workflow with TE100

Step 1.

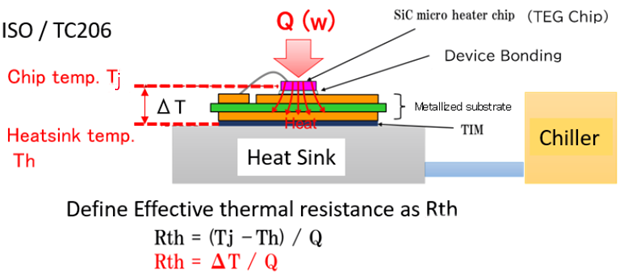

Prepare your sample substrate by attaching a TEG Chip* to simulate next-generation power devices in driving mode

Step 2.

Place the prepared sample on a water-cooled heat sink

Step 3.

Plug in the TEG chip and heat up

Step 4.

Find the temperature difference (ΔT) between the registered temperature of the TEG chip and the heat sink

Step 5.

Calculate the thermal resistance value (Rth) of the sample substrate

Thermal resistance (Rth) = Temperature difference (ΔT) between TEG chip and heat sink / divided by electric power (Q)

*What is a TEG chip?

This self-heating device is made of silicon carbide (SiC) with a heat resistance of 250°C or higher.

During measurement, the TE100 analyzer applies a 10kg load on top of the substrate sample.

This way, we're not just estimating; we're accurately stimulating the kind of real-world workload these packaging materials and insulating substrates will endure.

Why do you need thermal resistance values (K/W) from metalized substrates?

Find out how application-based test data via a new ISO method helps you overcome thermal challenges in next-generation power modules.

Device Configuration

TE100

Main Control Unit (left) and Measurement Unit (right)

CFA302

Constant Temperature Water Circulation Device

Thermoelectric Generator (TEG) Chip

During measurement, the TEG chip is attached to a substrate sample for thermal resistance analysis.

Monitor, Keyboard, and Mouse

(supplied by the user)

Set up a call to find out how to increase your semiconductor yield

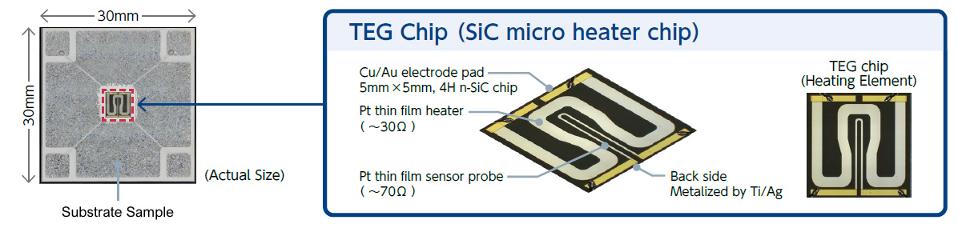

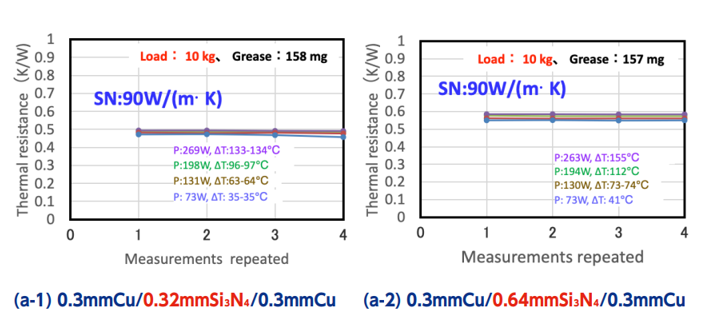

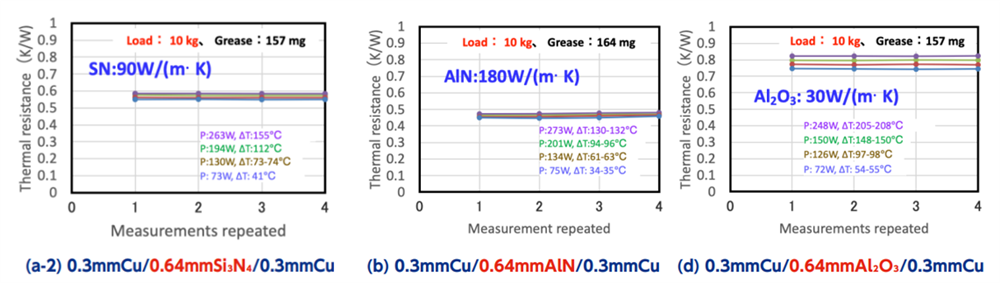

Measurement results (reference)

The thermal resistance value varies with the thickness of the substrate, specifically for Silicon Nitride (Si3N4). The variation in thermal resistance is directly related to the substrate's thickness.

Thermal resistance value is also influenced by the type of material used for the packaging board. A comparative analysis of three materials - Silicon Nitride (Si3N4), Aluminum Nitride (AlN), and Aluminum Oxide (Al2O3) - demonstrates that the thermal resistance value changes based on the board material.

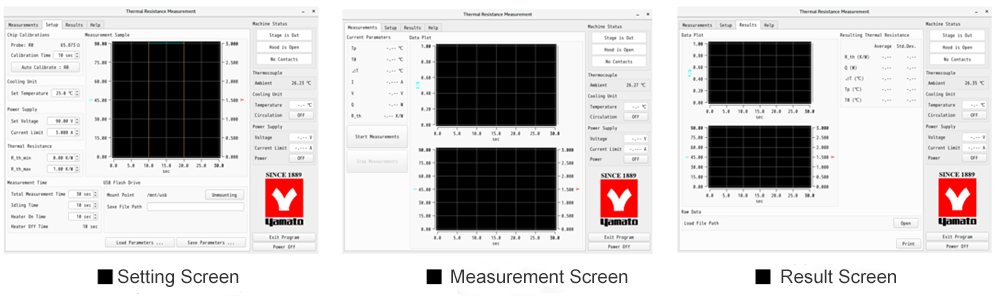

Standard equipped with analysis system software

The operation screen has a streamlined interface, featuring "Settings", "Measurement", "Results" and "HELP" sections.

Patented Design and ISO-compliant Testing Method

Not only is the TE100 the world’s first and only thermal analyzer for semiconductor substrates, it has been awarded a patent, and the ISO has established a brand new testing protocol based on its applications.

For more information, please visit: ISO 4825-1:2023

Set up an informative call now