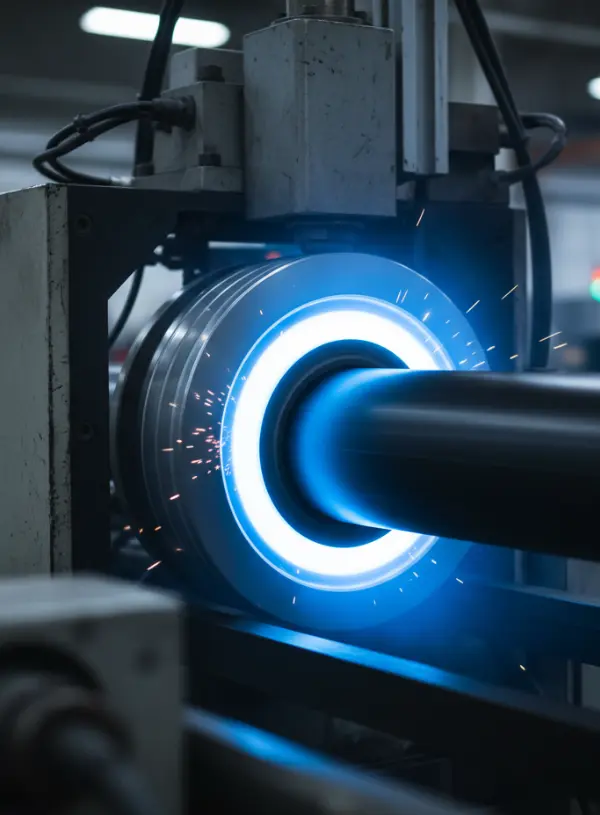

Printing on HDPE Pipe with Atmospheric Plasma

How to use an inline atmospheric plasma treater to raise surface energy on HDPE so inkjet or contact printing bites instantly, reducing smears and rework.

HDPE pipe is notoriously difficult to print on. Watch an inkjet printer try to mark untreated HDPE - the ink beads up like water on a freshly waxed car, smears at the slightest touch, or wipes away completely. This isn't just frustrating; it's expensive. Failed batch codes mean regulatory headaches. Illegible safety markings create liability risks. Every smeared print is another pipe heading for rework.

So why does ink fail to stick to untreated HDPE pipe? Surface energy that's simply too low for ink to grab onto.

HDPE naturally sits at 30-32 dynes/cm - well below the 40+ dynes/cm threshold that inks need for proper wetting and adhesion. The material's smooth, non-polar hydrocarbon structure actively resists bonding. It's chemically similar to trying to write on Teflon.

And we’re going to help you print on it.

If you don’t want to learn about this and you just want the plasma treater we built for printing on HDPE pipe, you can submit for a quote in 20 seconds.

How Does Atmospheric Plasma Treatment Transform HDPE Surface Energy?

Atmospheric plasma treatment bombards the HDPE surface with ionized gas, fundamentally changing its chemistry at the molecular level. This isn't surface roughening or coating. It’s more like molecular reconstruction.

The plasma introduces polar functional groups (hydroxyl and carbonyl) directly onto the pipe surface. These groups act like molecular anchors for ink. Surface energy jumps from that problematic 30-32 dynes/cm to a robust 42-50 dynes/cm in a single pass.

At the same time, it performs a micro-cleaning action, removing the invisible contamination layer that further inhibits adhesion. Oil residues from extrusion, dust particles, oxidation - all vaporized instantly.

What happens for your product is immediate compatibility with both inkjet and contact printers. No waiting period. No additional prep. The treated surface is ready for printing the moment it exits the plasma field.

Why Choose Atmospheric Plasma Over Chemical Primers or Flame Treatment for HDPE?

Traditional surface prep methods come with serious baggage. Let's be specific about what you're avoiding.

Chemical primers and etchants

- Ongoing consumable costs that never stop.

- VOC emissions requiring ventilation systems.

- Hazmat disposal fees and regulatory paperwork.

- Worker exposure risks requiring PPE protocols.

- Inconsistent application leading to variable results.

Flame treatment

- Open flames near production lines (what could go wrong?).

- Risk of pipe deformation from heat exposure.

- Inconsistent coverage on curved surfaces.

- Natural gas consumption adding to operating costs.

- Line stops that melt product surfaces.

Corona treatment

- Limited penetration depth (surface-only effect).

- Poor performance on three-dimensional pipe surfaces.

- Ozone generation requiring extraction.

Atmospheric plasma eliminates these issues entirely. It uses only air and low electrical consumption. No flames, no chemicals, no consumables beyond electricity. The non-contact design means no thermal damage or dimensional changes to your pipe.

What Production Challenges Does Inline Plasma Treatment Actually Solve?

Think about your current reject rate for printing defects. Every smeared code, every fading mark, every illegible safety warning - they all trace back to adhesion failure and expenses for your workplace. Here's what changes with plasma:

First-pass success rates

jump dramatically. Crisp, high-contrast prints stick immediately and permanently.

Rework time

drops to near zero. No more manual cleaning and reprinting.

Compliance confidence

increases. Batch codes and safety markings remain legible throughout the product lifecycle.

Line speed

can actually increase. No drying time for primers, no waiting for flame-treated surfaces to cool.

Yamato's inline design integrates directly into existing extrusion or printing lines. The adjustable treatment head matches your pipe diameter and line speed. Programmable controls lock in optimal treatment conditions - set it once, get consistent results every batch.

How Much Surface Energy Increase Is Actually Needed for Reliable Ink Adhesion?

The magic number for most printing applications is 40 dynes/cm minimum. Below that, you're gambling with adhesion. Above 40, you're in the safe zone where inks wet out properly and form durable bonds.

Yamato's atmospheric plasma treater reliably achieves 42-50 dynes/cm - comfortably above the threshold with room to spare. This isn't barely making it work; this is creating a surface that inks genuinely want to bond with.

You can verify this yourself with simple dyne pens or contact angle measurements. Watch water droplets spread flat instead of beading. See ink flow smoothly instead of retracting. The difference is immediately visible.

Does Plasma Treatment Affect HDPE Pipe Strength or Dimensions?

No. This is surface chemistry, not structural modification.

The plasma field only penetrates a few molecular layers - we're talking nanometers, not millimeters. The bulk properties of your HDPE remain completely unchanged. No thermal stress, no mechanical deformation, no dimensional changes.

The non-contact nature of atmospheric plasma is crucial here. Unlike flame treatment that can cause localized melting during line stops, or mechanical abrasion that removes material, plasma treatment leaves your pipe geometry intact while transforming only the outermost molecular layer.

How Long Does the Plasma-Treated Surface Remain Print-Ready?

Surface activation from plasma treatment remains effective for hours to days, depending on storage conditions. But here's why that timeframe rarely matters: inline integration.

When your plasma treater sits directly upstream of your print head, treatment-to-print time is measured in seconds, not hours. The activated surface gets printed immediately at peak receptivity. No degradation, no contamination, no second-guessing whether the treatment is still effective.

For operations that must treat and store, keeping pipes in clean, dry conditions maintains surface activation longer. But the real solution is inline integration - treat it, print it, ship it.

Can Plasma Treatment Improve More Than Just Ink Adhesion on HDPE?

Absolutely. That same surface activation that helps ink stick also works for.

Adhesive labels that won't peel at the edges

Protective coatings that actually protect

Secondary bonding operations for fittings or accessories

Paint systems for color-coding or branding

Any process that requires good surface wetting benefits from plasma treatment. You're not just solving a printing problem - you're creating a more bondable surface for any subsequent operation.

What Throughput Can Atmospheric Plasma Systems Handle for Pipe Production?

A Yamato plasma system scales with your production. Yamato's adjustable power and treatment head design match your line speed rather than forcing you to slow down for treatment.

Running 50 feet per minute? 100? 200? The plasma field intensity adjusts to deliver consistent dyne levels regardless of speed. Unlike batch chemical treatments or fixed-intensity flame systems, atmospheric plasma flexes with your production demands.

Key factors for throughput optimization:

Treatment width matches pipe diameter (no wasted energy treating air).

Power scales with line speed (faster lines, higher intensity).

Multiple treatment heads for large-diameter pipes.

Instant on/off capability (no warmup, no cooldown).

What Are the Real Safety and Environmental Benefits of Plasma Treatment?

Let's talk about what's not in your facility when you switch to plasma.

- No natural gas lines running to treatment stations

- No open flames near operators or materials

- No chemical storage requiring special ventilation

- No VOC exposure monitoring required

- No operator burns or gas inhalation risks

- Zero chemical waste streams to manage

- No greenhouse gas emissions from combustion

- No ozone-depleting substances

- No hazardous waste disposal contracts

- Alignment with ISO 14001 environmental standards

This isn't greenwashing - it's fundamental to how plasma works. You're using electricity to ionize air. That's the entire consumable list.

What ROI Can HDPE Pipe Manufacturers Realistically Expect?

The math is straightforward.

- Eliminate primer chemicals (thousands annually).

- Reduce rework labor (hours per shift).

- Cut scrap rates (every rejected pipe saved).

- Remove natural gas costs (for flame treatment users).

- Eliminate disposal fees (no chemical waste).

- Fewer customer complaints about illegible markings.

- Reduced liability from non-compliant safety markings.

- Faster throughput from eliminated drying times.

- Higher line utilization from reduced downtime.

Most operations see payback within 12-18 months just from eliminated consumables and reduced rework. Factor in the productivity gains and compliance confidence, and the ROI accelerates significantly.

Practical Setup. How to Integrate Atmospheric Plasma into Your HDPE Pipe Line

Integration is surprisingly straightforward.

1. Mount the treatment head at the optimal distance from pipe surface (typically 5-20mm).

2. Adjust treatment width to match pipe diameter.

3. Set plasma intensity based on line speed and target dyne level.

4. Position inline immediately before print head.

5. Program parameters into system controls for repeatability.

6. Validate with dyne testing and lock in settings.

The compact footprint of Yamato's plasma treater means it fits into existing lines without major retrofits. Most installations are producing treated, printed pipe within hours of equipment arrival.

Common Troubleshooting. Getting Optimal Results from Plasma Treatment

- Check distance consistency from treatment head to pipe surface

- Verify pipe is running true without wobble

- Adjust treatment width to ensure full coverage

- Increase plasma intensity or reduce line speed

- Check for contamination sources upstream

- Verify power supply is delivering rated output

- Minimize time between treatment and printing

- Check storage environment for contamination sources

- Consider inline integration if currently batch treating

Why This Matters. The Bigger Picture for HDPE Pipe Manufacturers

Reliable printing on HDPE pipe is about product traceability, regulatory compliance, brand reputation, and operational efficiency.

- Every smeared batch code is a quality question.

- Every illegible safety marking is a liability risk.

- Every hour spent on rework is profit walking out the door.

Yamato's atmospheric plasma treater delivers consistent adhesion improvement with zero chemicals, zero flames, and minimal footprint. It's not revolutionary technology - it's proven, practical, and profitable.

The 136-year heritage of Yamato brings Kaizen principles to every piece of equipment. Continuous improvement, elimination of waste, respect for people and process. Your plasma treater isn't just solving today's printing problems - it's built to deliver value for decades.

Ready to eliminate printing failures on your HDPE pipe production?

Get in touch with us here for application-specific testing and integration guidance. See the difference proper surface activation makes - first print, every print.