Converting Nano-Emulsions to Soft Granules.

A Rotary Evaporation Approach for Topical Pharma R&D

Your dermatology R&D team has perfected a nano-emulsion - stable, potent, and elegant - but it's messy, hard to dose, and difficult to scale. What if you could turn that same emulsion into soft, easy-to-handle granules without sacrificing stability?

This challenge surfaces repeatedly in topical pharmaceutical development. Liquid nano-emulsions offer remarkable advantages for drug delivery, yet their handling characteristics create bottlenecks in formulation workflows. The solution lies in precise, gentle conversion through rotary evaporation - a technique that transforms problematic liquids into manageable granules while preserving the nano-structure that makes these formulations so effective.

If you don’t want to learn about this, and you just want the rotary evaporator we built for this application, you can customize your topical pharma rotary evaporator package in less than 20 seconds.

What Exactly Are Nano-Emulsions and Why Do They Matter for Skin Delivery?

Nano-emulsions consist of oil and water phases stabilized by surfactants, with droplet sizes ranging from 20 to 200 nanometers. This microscopic scale fundamentally changes how formulations interact with skin. The tiny droplets penetrate deeper into the stratum corneum, solubilize poorly water-soluble actives more effectively, and maintain stability longer than conventional emulsions or microemulsions.

Creating these systems requires careful selection between preparation methods. High-energy approaches like high-pressure homogenization (up to 2000 bar), ultrasonication with probe or bath systems, and microfluidization using interaction chambers offer precise control over droplet size. Alternatively, low-energy techniques including phase inversion temperature (PIT) method, spontaneous emulsification, and solvent displacement provide gentler processing for sensitive compounds.

For topical and transdermal applications, nano-emulsions excel at delivering challenging actives. Corticosteroids achieve better penetration with reduced systemic absorption. Retinoids maintain stability while minimizing irritation. Antifungals reach deeper infection sites in onychomycosis treatment. Antioxidants like coenzyme Q10 and vitamin E resist degradation while enhancing bioavailability. These advantages explain why formulators persist despite the handling challenges.

Why Should I Convert My Liquid Nano-Emulsion Into Granules?

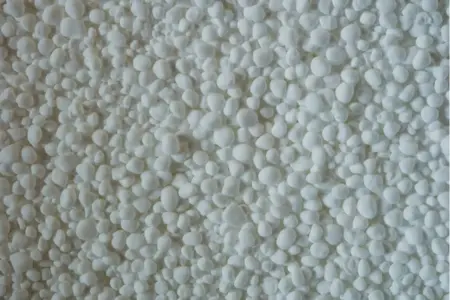

Converting nano-emulsions to soft granules addresses multiple R&D pain points simultaneously. The transformation eliminates spillage and contamination risks during handling, enables accurate weighing without specialized volumetric equipment, and reduces cold chain requirements for storage. Perhaps most importantly, it simplifies transport between facilities or to clinical sites - a critical consideration for multi-site studies.

Beyond practical handling, granulation extends shelf life significantly. When water activity drops below 0.6, microbial growth becomes impossible. Oxidation pathways slow dramatically in the solid state, and there's no risk of Ostwald ripening or phase separation that plague liquid systems. Light-sensitive compounds gain enhanced photostability when incorporated into an opaque granule matrix.

For R&D teams, granules offer unprecedented formulation flexibility. They integrate seamlessly into hybrid dosage forms - imagine an ointment base enhanced with suspended nano-emulsion granules that release active ingredients at controlled rates. This approach enables texture customization and release profile engineering that liquid systems cannot match. Each granule contains the same ratio of components, ensuring uniform drug distribution in the final product and accelerating formulation optimization by reducing variability between experimental batches.

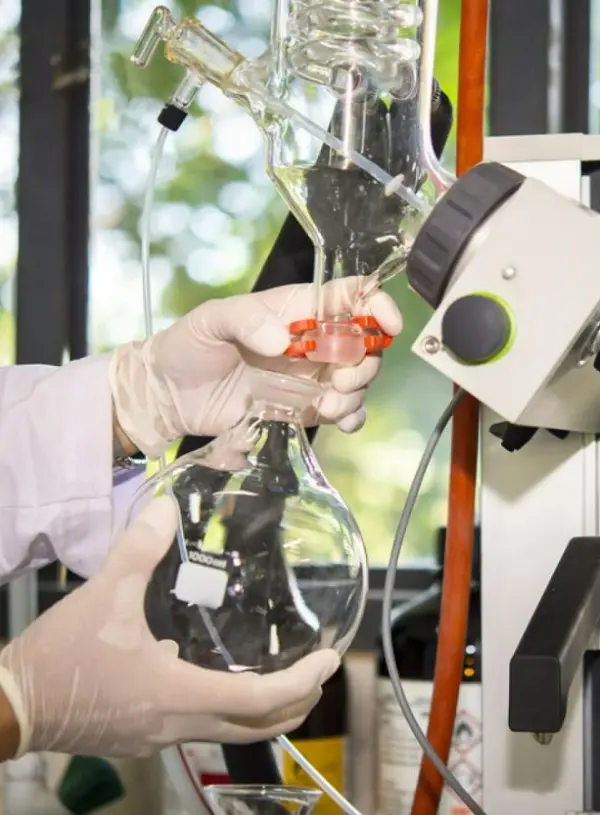

How Does Rotary Evaporation Actually Convert Liquids to Granules?

Rotary evaporation transforms liquid nano-emulsions into granules through controlled solvent removal under reduced pressure. The process sounds simple, but the physics protect the delicate nano-structure throughout conversion.

As the flask rotates, the emulsion forms a thin film across the interior surface - typically 0.1 to 0.5 mm thick. This maximizes surface area for evaporation while minimizing the time any portion of the sample experiences heat. The reduced pressure lowers solvent boiling points by 20-50°C compared to atmospheric conditions, enabling removal at temperatures that won't destabilize temperature-sensitive APIs or disrupt the surfactant architecture maintaining droplet integrity.

The rotation itself serves multiple critical functions. It ensures even heat distribution from the water bath, prevents local overheating that could trigger phase separation, and maintains uniform drying across the entire sample. As solvents evaporate, the remaining components gradually concentrate and solidify into granules. The continuous motion prevents aggregation and ensures consistent particle formation.

Critical to success is maintaining the nanoscale structure until the continuous phase is gone. Too rapid evaporation causes droplet coalescence. Excessive heat triggers phase separation. Insufficient vacuum leaves residual moisture that compromises stability. The process demands precise control over temperature, vacuum level, and rotation speed - parameters that directly determine granule quality.

What Equipment Features Make the Difference in Nano-Emulsion Processing?

The Yamato Mini Rotary Evaporator addresses specific nano-emulsion granulation demands through targeted engineering choices. The wide speed range of 5 to 315 rpm allows formulators to dial in the exact rotation rate that balances film formation with gentle handling.

Low speeds (5-30 rpm) work best for high-viscosity emulsions and shear-sensitive proteins, where aggressive mixing could damage the delicate structures. Medium speeds (30-100 rpm) suit standard pharmaceutical emulsions, providing efficient mixing without excessive shear. High speeds (100-315 rpm) accelerate processing for low-viscosity systems or when time constraints demand faster throughput.

Temperature management extends from ambient to 90°C with digital bath control, while optional cooling circulation protects heat-labile compounds like certain vitamins and biologics. The vacuum system, controllable from 2 to 1000 mbar, prevents the bumping and foaming common with surfactant-rich systems while enabling staged solvent removal for mixed-solvent formulations.

Programmable automation transforms what could be a variable process into a reproducible standard operating procedure (SOP). Temperature profiles, vacuum ramps, and rotation sequences execute precisely every time. This consistency matters when validating processes or transferring methods between sites. A formulator in Tokyo can share their exact parameters with a colleague in New Jersey, confident the results will match.

How Can I Maintain Droplet Integrity During the Drying Process?

Preserving the nano-structure requires careful attention to several critical parameters throughout the conversion process.

Temperature control proves paramount - stay 10-15°C below the cloud point or phase inversion temperature to prevent droplet coalescence. Use gradient heating, starting at 25°C and increasing by 5°C every 30 minutes, while monitoring for color changes that indicate phase separation. For particularly sensitive systems, the bath temperature should never exceed 40°C, even if this extends processing time.

Vacuum optimization begins at partial vacuum (400-500 mbar) to prevent violent boiling that could disrupt the emulsion structure. Gradually decrease to 50-100 mbar as viscosity increases, adjusting based on foaming behavior - surfactants often require slower transitions to prevent excessive foam formation that can carry material into the condenser.

Rotation speed must match viscosity changes: start slow with fresh emulsion, then increase as the material concentrates. Watch for "climbing" - when material creeps up flask walls, it indicates excessive speed that could compromise droplet integrity. For extremely shear-sensitive biologics, consider intermittent rotation patterns that provide mixing without continuous stress.

The Yamato system's precise control over these variables enables formulators to develop and validate robust methods that preserve the therapeutic benefits of the nano-emulsion architecture while achieving the practical advantages of a granulated product.

What Excipients and Additives Optimize Granule Formation?

Selecting the right excipients dramatically impacts granule quality and performance. Matrix formers like maltodextrin (DE 10-20) create compressible, free-flowing granules ideal for tableting, while lactose monohydrate excels in immediate-release applications where rapid dissolution is critical. For moisture-sensitive APIs, mannitol provides a non-hygroscopic matrix that maintains stability even under challenging storage conditions.

Stabilizers and protectants preserve the active ingredient's integrity during and after processing. Trehalose stands out for preserving protein and peptide structure during drying - particularly important for biologics and biosimilars. Hydroxypropyl-β-cyclodextrin maintains drug solubility post-drying, preventing crystallization that could compromise bioavailability. For cost-sensitive projects, sucrose offers an economical alternative that still provides cryoprotection and bulking.

Flow and anti-caking agents, though used in small quantities (typically 0.5-2%), profoundly impact the final product's handling characteristics. Colloidal silicon dioxide prevents agglomeration during storage, while magnesium stearate reduces adhesion to processing equipment. These additions transform sticky, cohesive powders into free-flowing granules suitable for automated filling equipment.

How Do I Troubleshoot Common Granulation Problems?

Even well-designed processes encounter challenges. Understanding the root causes enables rapid resolution and process optimization.

Sticky, Tacky Granules That Won't Flow?

When granules stick together or adhere to equipment, incomplete drying is often the culprit. Extend process time or improve vacuum to remove residual moisture. If the formulation contains hygroscopic components, add desiccants like anhydrous calcium sulfate or switch to less hygroscopic alternatives. For systems with low glass transition temperatures, incorporate high-Tg polymers like HPMC to improve physical stability. Sometimes, implementing a post-drying equilibration step at 25% relative humidity allows moisture redistribution that eliminates surface tackiness.

Powder Instead of Granules?

If the process yields fine powder rather than discrete granules, the evaporation rate may be too aggressive. Reduce the rate to allow particle consolidation by lowering bath temperature or reducing vacuum. Adding binding agents (2-5% PVP or HPMC) provides the cohesion necessary for granule formation. Maintaining 2-5% residual moisture before final drying often helps particles agglomerate into the desired size range.

Non-Uniform Particle Size Distribution?

Inconsistent granule sizes typically stem from process variability. Ensure the starting emulsion is homogeneous through pre-homogenization or brief ultrasonication. Optimize rotation speed to match viscosity changes throughout the process - what works for the initial liquid won't suit the concentrated paste near the endpoint. Use step-wise vacuum reduction rather than continuous ramping to maintain better control over evaporation rates at different concentration stages.

What Are the Alternatives and When Should I Use Them?

Understanding when rotary evaporation isn't the optimal choice helps inform process selection and justify equipment investments.

Spray drying offers unmatched speed but sacrifices gentleness. With inlet temperatures typically ranging from 120-180°C, it stresses sensitive compounds even during brief exposure. The technology excels for heat-stable APIs with melting points above 150°C and production scales above 1 kg/batch. However, poor yields for small batches (<100 mL) and limited particle size control without extensive optimization make it less suitable for early R&D work.

Freeze drying (lyophilization) provides maximum protection with minimum throughput. It's ideal for biological drugs, vaccines, and probiotics where maintaining native structure is paramount. When water is the only solvent and extended shelf life (5+ years) is required, freeze drying becomes the default choice. However, cycle times of 24-72 hours per batch, energy consumption 3-5x higher than rotary evaporation, and capital costs exceeding $100,000 for research-scale units limit its routine use.

Fluid bed granulation works well for pilot and production scales above 5 kg, especially when coating and granulation must occur simultaneously. In GMP manufacturing environments, it's often the technology of choice. However, minimum batch sizes of 500g-1kg, complex setup and cleaning procedures, and poor reproducibility at small scale make it impractical for early-stage development.

For early-stage pharmaceutical development, rotary evaporation provides the optimal balance of gentleness, control, and efficiency. The ability to process 10-500 mL samples without waste makes it ideal for expensive APIs or scarce materials.

How Can I Scale Up From Benchtop to Pilot Production?

Successful scale-up depends on maintaining critical process parameters across equipment sizes. The key lies in preserving equivalent film thickness (typically 0.1-0.5 mm) and matching surface area to volume ratios between scales. Residence time in the heated zone must remain constant, which often requires adjusting rotation speeds proportionally to flask size.

Documentation becomes critical during scale-up. Record all process parameters including ramp rates, photograph granule appearance at each scale, and analyze particle size distribution and residual moisture across batches. Validate API content uniformity to ensure the process remains robust as batch sizes increase.

The Yamato system's programmable interface exports all parameters in GMP-ready format, simplifying technology transfer and regulatory submissions. This digital record proves invaluable when defending process changes during regulatory review or troubleshooting unexpected results during scale-up.

What Analytical Methods Confirm Successful Conversion?

Verifying that nano-structure survives granulation requires sophisticated characterization across multiple dimensions.

For particle and droplet analysis, dynamic light scattering (DLS) after reconstitution confirms that the original nano-emulsion droplet size is maintained. Scanning electron microscopy (SEM) reveals morphology changes, while X-ray powder diffraction (XRPD) detects unwanted crystallization. Differential scanning calorimetry (DSC) identifies thermal transitions that could impact stability.

Performance testing validates that granulation hasn't compromised therapeutic efficacy:

In vitro release testing using Franz diffusion cells compares release profiles between liquid and granulated forms

Rheological analysis of reconstituted systems ensures the original texture is recovered

Zeta potential measurement predicts long-term stability

Antimicrobial effectiveness testing confirms preservative efficacy remains adequate

Quality control parameters ensure regulatory compliance. Karl Fischer titration determines moisture content (typically targeting <5%), while gas chromatography confirms residual solvents meet ICH Q3C limits. HPLC quantifies API content and monitors for degradation products, and laser diffraction provides granule size distribution data for batch release.

Can This Process Work With Lipid Nanoparticles and Other Advanced Systems?

The principles extend beyond traditional nano-emulsions to cutting-edge delivery systems. Solid lipid nanoparticles (SLN) require processing below the lipid melting point to maintain their solid state, with cryoprotectants preventing aggregation during concentration. Nanostructured lipid carriers (NLC), containing liquid lipid domains within a solid matrix, demand precise temperature control to preserve their unique architecture.

Liposomes and niosomes, with their bilayer structures, need special consideration. Including membrane stabilizers like cholesterol maintains structural integrity, while gradient hydration techniques during reconstitution ensure proper reassembly. Monitor bilayer integrity through size exclusion chromatography to confirm the vesicles survive the granulation process intact.

These advanced systems often require protocol modifications - slower evaporation rates, lower temperatures, or specialized excipients - but benefit from the same gentle processing advantages that make rotary evaporation ideal for sensitive pharmaceutical materials.

What's the Real ROI for R&D Teams?

Converting nano-emulsions to granules through rotary evaporation delivers measurable returns across multiple dimensions.

Time savings materialize through reduced formulation optimization cycles - what previously took months now completes in weeks. Stability-related reformulation becomes rare when moisture is eliminated as a variable. Clinical supply preparation accelerates when you're shipping stable granules instead of temperature-sensitive liquids.

Cost reductions accumulate from multiple sources. API waste drops dramatically with small-batch capability - process 50 mL instead of the 500 mL minimum required for spray drying. Cold storage requirements disappear for many formulations, reducing both equipment needs and energy consumption. Specialized handling equipment becomes unnecessary when dealing with free-flowing granules instead of viscous emulsions.

Innovation enablement represents perhaps the greatest value. Access previously unfeasible drug-excipient combinations that wouldn't survive spray drying. Create differentiated products with unique release profiles by combining multiple granule types. Patent novel delivery systems and manufacturing methods that competitors using conventional techniques cannot replicate.

The Yamato Mini Rotary Evaporator, at 10-20% lower cost than comparable instruments, delivers these benefits while respecting laboratory space and budget constraints.

The Path Forward: Implementing Nano-Emulsion Granulation

Converting nano-emulsions to granules through rotary evaporation solves real problems in topical pharmaceutical development. The technique transforms difficult-to-handle liquids into stable, manageable solids while preserving the nano-architecture responsible for enhanced drug delivery.

For teams developing next-generation topical products - whether prescription dermatologicals, cosmeceuticals, or OTC formulations - mastering this conversion technology opens new formulation possibilities. The ability to create stable, elegant dosage forms from challenging actives accelerates development timelines and expands therapeutic options.

Start with a simple model system: prepare a vitamin E nano-emulsion, convert it to granules using the parameters outlined here, and confirm structure preservation through particle size analysis. This proof-of-concept builds confidence before moving to more complex APIs and multi-component systems.

The investment in proper equipment and process understanding pays dividends through improved product quality, reduced development time, and enhanced formulation flexibility. With the right tools and knowledge, your team can transform those problematic liquid nano-emulsions into robust, scalable dosage forms ready for clinical evaluation and commercial success.