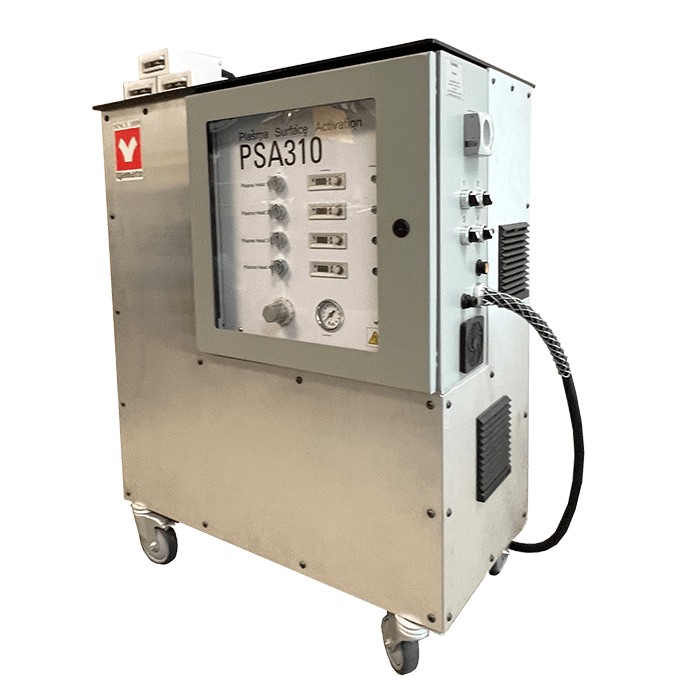

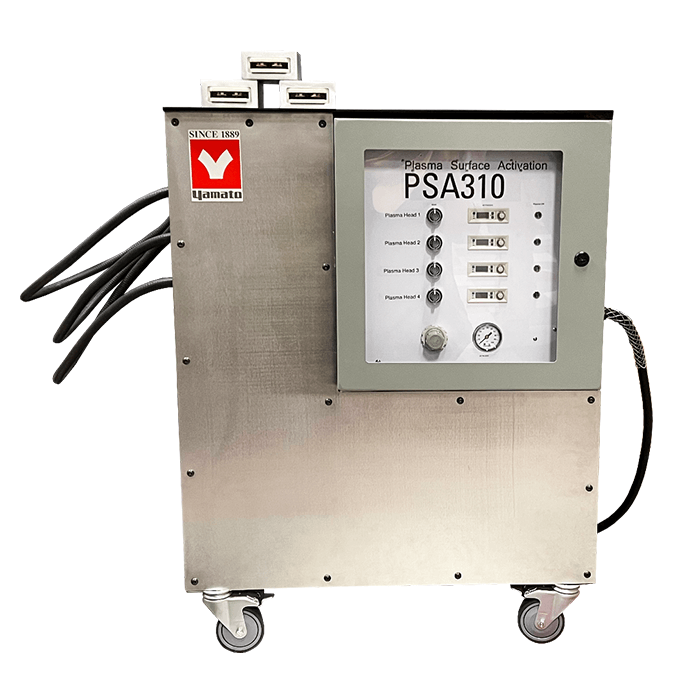

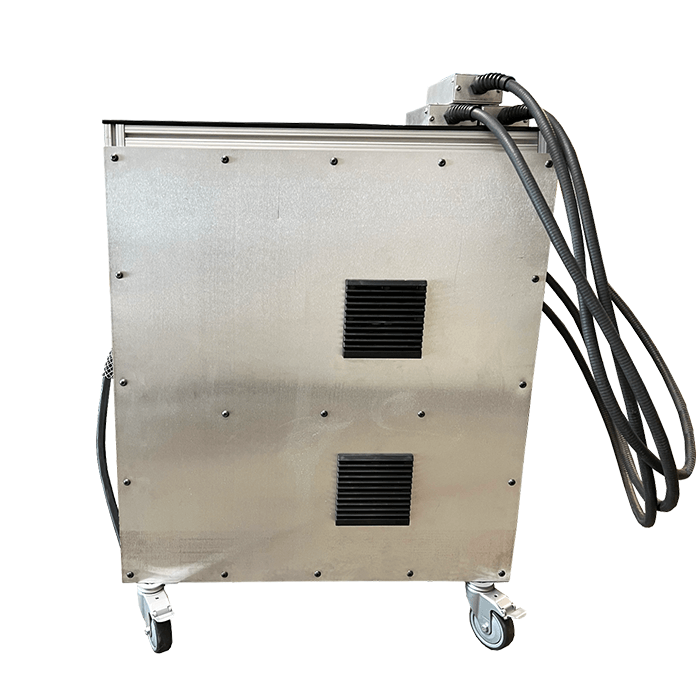

Yamato Plasma Treater

Dramatically increase surface wettability for better adhesion.

- Reduce defects and budget wasted on rework.

- Speed up processes that previously relied on chemical surface prep.

- Produce higher quality products that increase the lifetime value of your customers.

- Slash the costs associated with solvent disposal in your process.

Plasma Treater for Precision Surface Treatment and Exceptional Adhesion

Reduced production costs through less material waste and faster processes.

Increased operational efficiency, enabling faster time to market.

Higher product quality, reducing defects, reworks, and customer complaints.

Stronger customer satisfaction due to more durable, high-quality products.

Cost savings from using fewer materials and lower labor costs for rework.

Plasma Treatment for printing on HDPE pipe

High-density polyethylene (HDPE) pipe industry

HDPE pipes are used for oil and gas, chemicals, agriculture, water networks, sewage/drainage, ducting, mining, and telecommunications.

What was used before plasma treatment?

Before plasma, a flame torch was used to activate the surface of the pipe prior to printing.

Why this manufacturer switched to plasma treatment

Safety

*No open flames or explosion risks.

*No operator burns.

*No gas inhalation risks.

Budget

*Only air and low electrical consumption involved.

Quality

*No melting of product during line stops.

Corporate goals

*Elimination of natural gas use.

*Lower resource consumption linear foot of HDPE.

Air plasma treater for a better bond & a repeatable outcome.

You need surfaces that perform - for bonding, coating, or printing. Plasma surface treatment machines prepare more welcoming surfaces by boosting wettability and adhesion strength, setting you up for success.

Why do you care?

Stronger bonds

Improved adhesion means fewer failures and a more durable final product.

Faster production

Reduce waste, speed up processes, and create more reliable products.

Eco-friendly

Meet your corporate sustainability goals at the same time as your product quality goals.

In the lab, and in industries like electronics, medical devices, semiconductors, packaging, and automotive, every detail counts. A plasma treater machine gives you a more suitable surface without the hassle of chemical surface preparation methods.

Not sure if a plasma treater is the update your process needs?

This guide will help you decide (without trying to sell you).

Our engineers put their heads together to bring you a comprehensive guide outlining applications that benefit from plasma treatment, and how exactly you can qualify those benefits. Get tips for identifying the features you need, understand the features that actually make a difference in your application, and crystalize the questions you should ask your supplier whether you choose to work with us or not.

Where do other labs and businesses use plasma surface treaters?

Customizable plasma surface treatment machines are used across industries to prepare surfaces for lasting adhesion.

Electronics manufacturing

Plasma surface treatment is widely used to improve the adhesion of solder masks and coatings in circuit boards. By removing microscopic contaminants, oxygen plasma treatments ensure better wettability and adhesion, which leads to more reliable electrical connections.

Case study - semiconductor manufacturing

Plasma surface treatment is critical before bonding wire to semiconductor surfaces. By cleaning away organic contaminants and oxides, plasma ensures stronger, more reliable connections. Companies like Intel and Samsung have integrated plasma cleaning in their semiconductor production lines to improve product reliability.

Medical device manufacturing

Medical devices, especially implants and tools, require biocompatible surfaces to ensure proper function and safety. Plasma surface activation is used to treat surfaces like silicone, plastics, and metals, preparing them for bonding, coating, or sterilization. Plasma treatment increases adhesion strength for coatings like hydrophilic layers that make medical devices function optimally inside the body.

Case study - catheter manufacturing

Medical device manufacturers like Medtronic and Abbott use plasma surface activation to enhance the adhesion of hydrophilic coatings on catheters, ensuring the coating remains intact during insertion and use. Plasma-treated surfaces also reduce friction, improving patient comfort and device efficacy.

Automotive

In automotive manufacturing, surfaces need to withstand extreme conditions, and plasma activation ensures they do. Whether it’s prepping a surface for painting or bonding divergent materials like metal and plastic, plasma cleaning ensures surfaces are contaminant-free, improving adhesion strength and product longevity.

Case study - automotive glass bonding

Companies like BMW and Tesla use plasma surface treatment machines to prepare the glass surfaces of windshields before bonding them to car frames. Plasma cleaning ensures that the adhesives used for bonding glass to metal adhere securely, creating stronger, long-lasting bonds that withstand temperature and environmental changes.

Aerospace

In the aerospace industry, components must endure extreme stresses and high-performance standards. Plasma cleaning plays a crucial role in preparing surfaces for bonding composite materials, metals, and adhesives used in aircraft and spacecraft components.

Case study - composite bonding for aircraft

Boeing and Airbus use plasma surface treatment processes to prepare the surfaces of carbon fiber composites before applying adhesives in the aircraft assembly process. Plasma cleaning removes contaminants that could compromise the bond, resulting in safer, stronger aircraft components that can handle extreme forces during flight.

Packaging and printing

Plasma surface activation is also widely used in the packaging and printing industries to enhance the printability of materials. Surfaces like plastic films and metals can be difficult to print on without proper surface treatment. Plasma activation prepares these surfaces by increasing wettability, allowing inks and adhesives to bond more effectively.

Case study - flexible packaging

Companies in the food and consumer goods industries use plasma treatments to prepare plastic films before printing. By increasing surface energy, plasma treatments ensure that inks adhere properly, resulting in high-quality, long-lasting prints on flexible packaging. Companies like Amcor and Tetra Pak utilize this process in their packaging lines.

What does improved wettability and printability really mean for me?

Your business, or your employer, cares deeply about the outcomes of new processes. Here’s what atmospheric plasma treatment means down the line.

Surface cleaning solvents in your surface now

Surface cleaning solvents in your surface tomorrow

Better adhesion for coatings, inks, and bonding gives you reduced production costs and higher quality end products, leading to fewer rejections or returns from customers and increased customer satisfaction.

By improving wettability, surfaces become more receptive to coatings, inks, or adhesives. This leads to fewer defects, stronger bonds, and reduced material waste, which means fewer production errors and higher product quality.

Faster production speeds and increased efficiency gives you increased throughput and faster time-to-market, which boosts operational efficiency and revenue potential.

Improved wettability ensures faster drying and curing times for inks, adhesives, or coatings. This accelerates production processes and reduces bottlenecks in the manufacturing line.

Lower material costs give you cost savings, making production more cost-effective.

Because surfaces treated with plasma cleaning have improved adhesion, businesses need less ink, adhesive, or coating to achieve the desired results.

Improved product durability and performance give you longer-lasting products that build your reputation, increasing brand loyalty and repeat business.

Products with enhanced adhesion are more durable, meaning they last longer and perform better under stress (e.g., medical devices, electronics, automotive parts).

Reduced need for rework and defects gives you lower labor costs and less downtime due to quality issues.

With better wettability and adhesion, there’s less chance of product failures, such as coatings peeling off or bonds weakening.

Alignment with your corporate goals gives you a leg up on your competitors.

Plasma cleaning allows for adhesion improvements without the use of chemicals, making the process more environmentally friendly and often compliant with stringent environmental regulations.

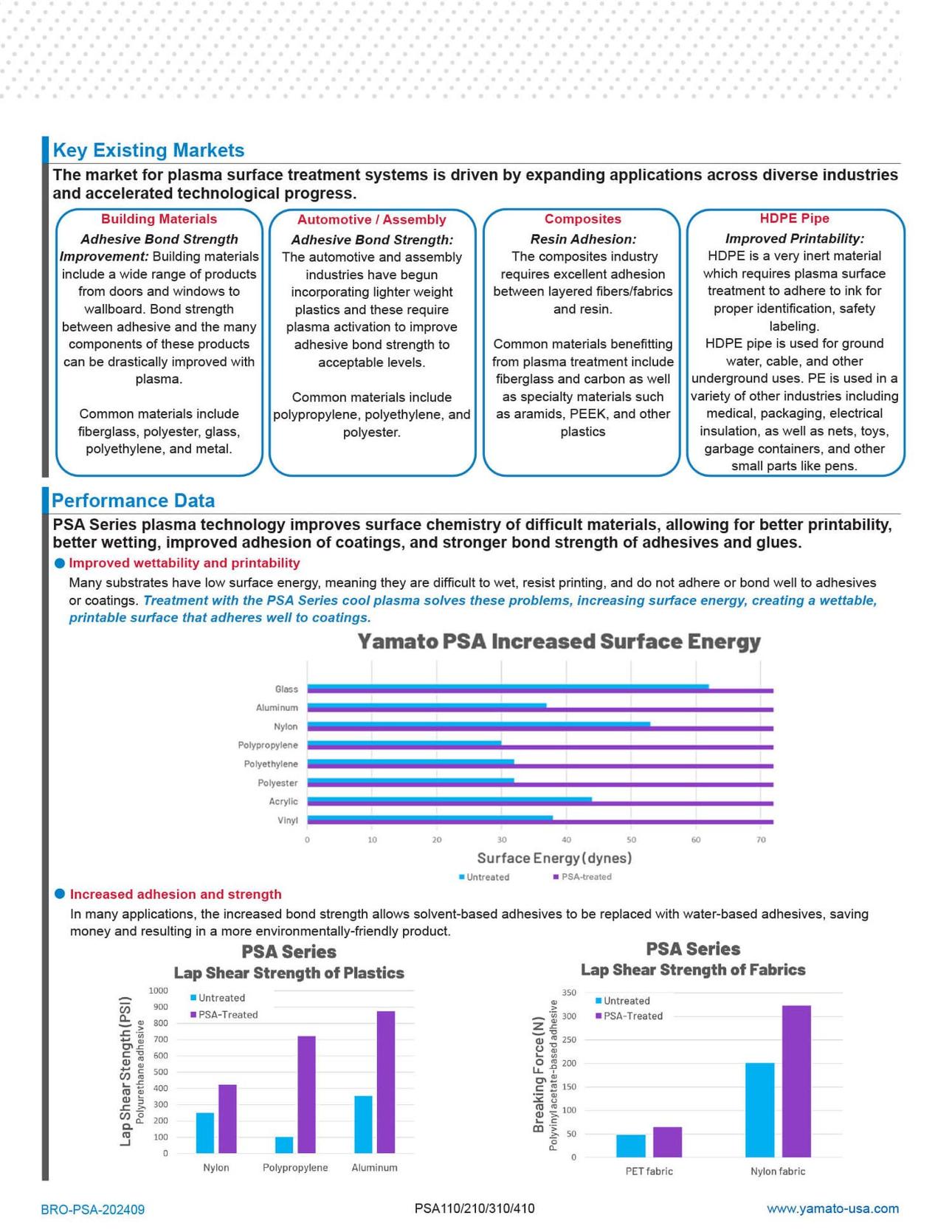

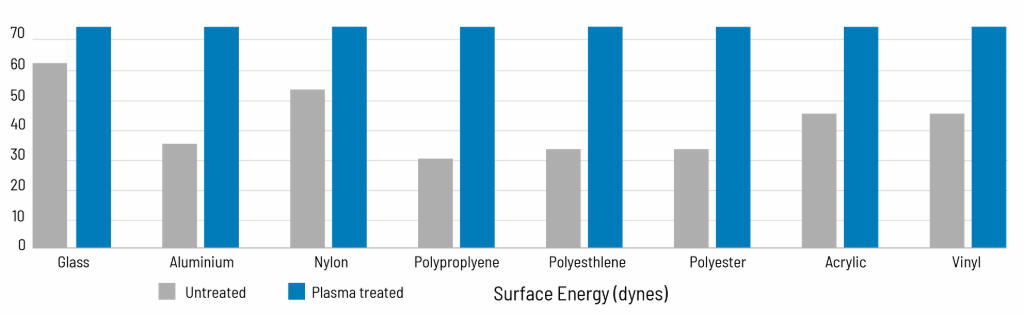

Many substrates have low surface energy, meaning:

- They are difficult to wet

- They resist printing

- They do not adhere or bond well to adhesives or coatings

Treatment with plasma solves these problems, increasing surface energy, and creating a wettable, printable surface that adheres well to coatings.

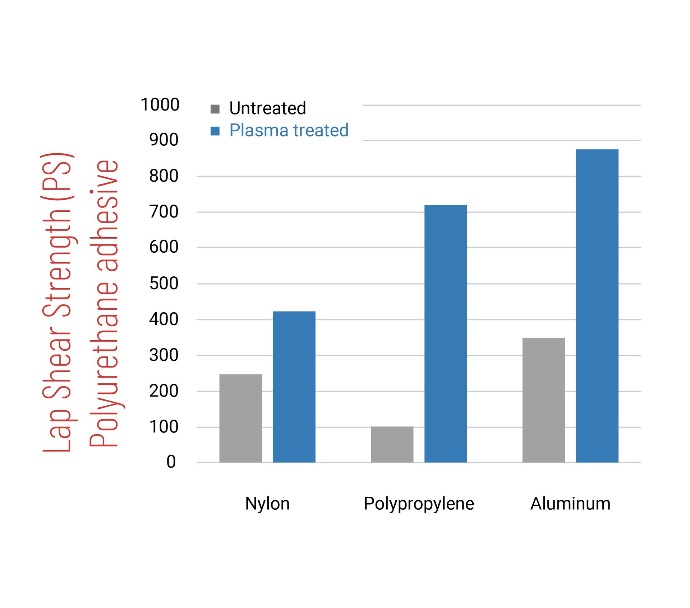

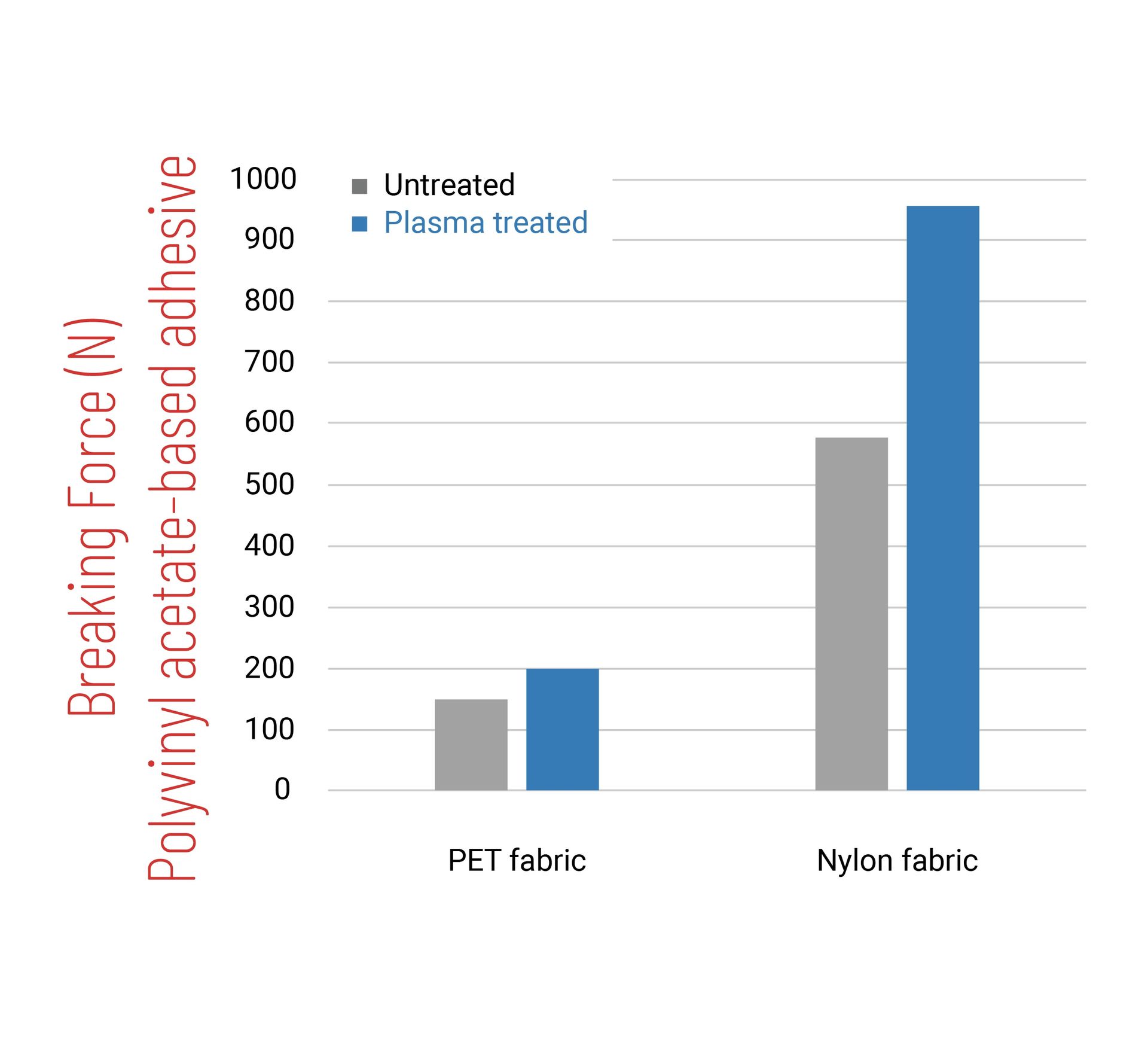

What does adhesion strength really mean for me?

Higher reliability in end products, leading to fewer product failures and a longer product lifespan. This improves customer satisfaction and reduces the risk of warranty claims or product recalls.

Faster assembly times and simplified manufacturing processes, leading to lower labor costs and higher production efficiency.

Improved product aesthetics enhances the visual appeal of the product, which can result in higher perceived value and the ability to command premium pricing.

Reduced liability risk, fewer legal complications, and a stronger reputation for safety and quality. This also minimizes the financial risks associated with product recalls or litigation.

Improved product performance in challenging environments, making the product more versatile and opening up new market opportunities in industries that require high-stress tolerance (e.g., aerospace, automotive, electronics).

Lower material costs, reduced time spent on applying adhesives, and less waste, all contributing to overall production cost savings.

The plasma surface treatment process generates powerful chemical surface reactions that increase bond strength between difficult substrates and adhesives, improving the integrity and durability of composites. In many applications, the increased bond strength allows solvent-based adhesives to be replaced with water-based adhesives, saving money and resulting in a more environmentally friendly product.

Made in

the USA

Cool Plasma Technology

Fast

Production Speed

Achieve Atomic Cleanliness

Reduce Solvents in

Your Application

Cut Your Chemical Budget

Lower Your Lab’s Environmental Impact

Eliminate Solvent Disposal

Prepare Semiconductor Surfaces Quickly

Improve Quality

of Bonding

Made in the USA

Reduce Solvents in

Your Application

Cool Plasma Technology

Cut Your Chemical Budget

Fast Production Speed

Lower Your Lab's Environmental Impact

Achieve Atomic Cleanliness

Eliminate Solvent Disposal

Prepare Semiconductor Surfaces Quickly