Bumping poses a frequent challenge during evaporation processes, often resulting in sample loss and contamination. This issue typically arises when applying excessive heat or vacuum pressure to a specific application, or using flasks that are too small.

Here's what our customers in food and health sciences have shared:

"In our research, we extract lipids from vegetables and analyze phospholipids and glycolipids components. Given the low lipid content in vegetables, we handle large sample volumes and aqueous solvents. Bumping has always been a persistent concern when using rotary evaporators for concentration and separation.

To mitigate this issue, we manually open and close the cock to prevent rapid boiling, a task that proves difficult and labor-intensive. This challenge resonates with many other labs."

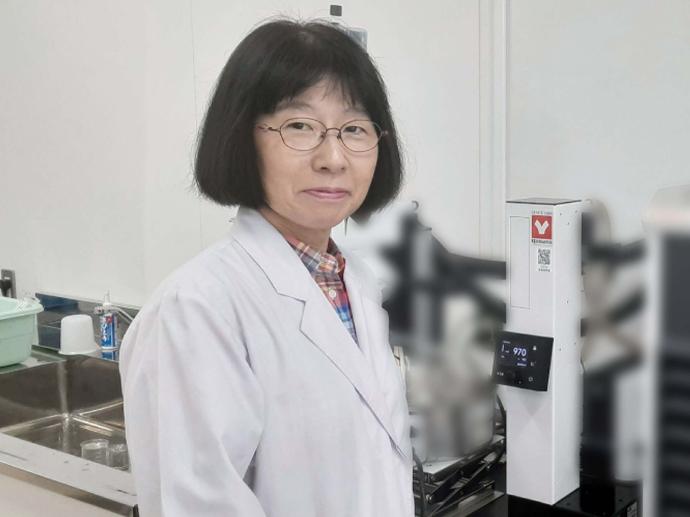

Professor Eiko Sugiyama

Why don’t bump traps work?

A bump trap serves as a smaller secondary flask positioned above the main flask in a rotary evaporator setup. Its purpose is to capture any sample that splashes or "bumps" during the evaporation process, preventing it from being drawn into the rest of the apparatus.

However, while bump traps prevent sample loss, they do not effectively reduce bumping itself.

While bump traps might reduce some risks of contamination, evaporating high-boiling point solvents such as water remains a time-consuming and demanding task.

Avoid solvent contamination the old-fashioned way

Bumping occurs when the sample undergoes rapid boiling and bubbling, causing the liquid being concentrated to splatter out of the vessel.

The traditional way to avoid bumping during evaporation is through visual inspection. Lab technicians often have to watch the samples during evaporation and manually adjust the vacuum pressure so that bumping doesn’t occur.

Here's another testimonial from a PI of an applied chemistry lab:

“We use infrared spectroscopy to do surface analysis of catalysts, chemical heat storage materials, and adsorbents. When loading active ingredients onto catalysts and adsorbents, we use aqueous solutions as solvents, which we need to remove at a later stage. Drying high boiling point solvent, like water, used to take us 4 hours.”

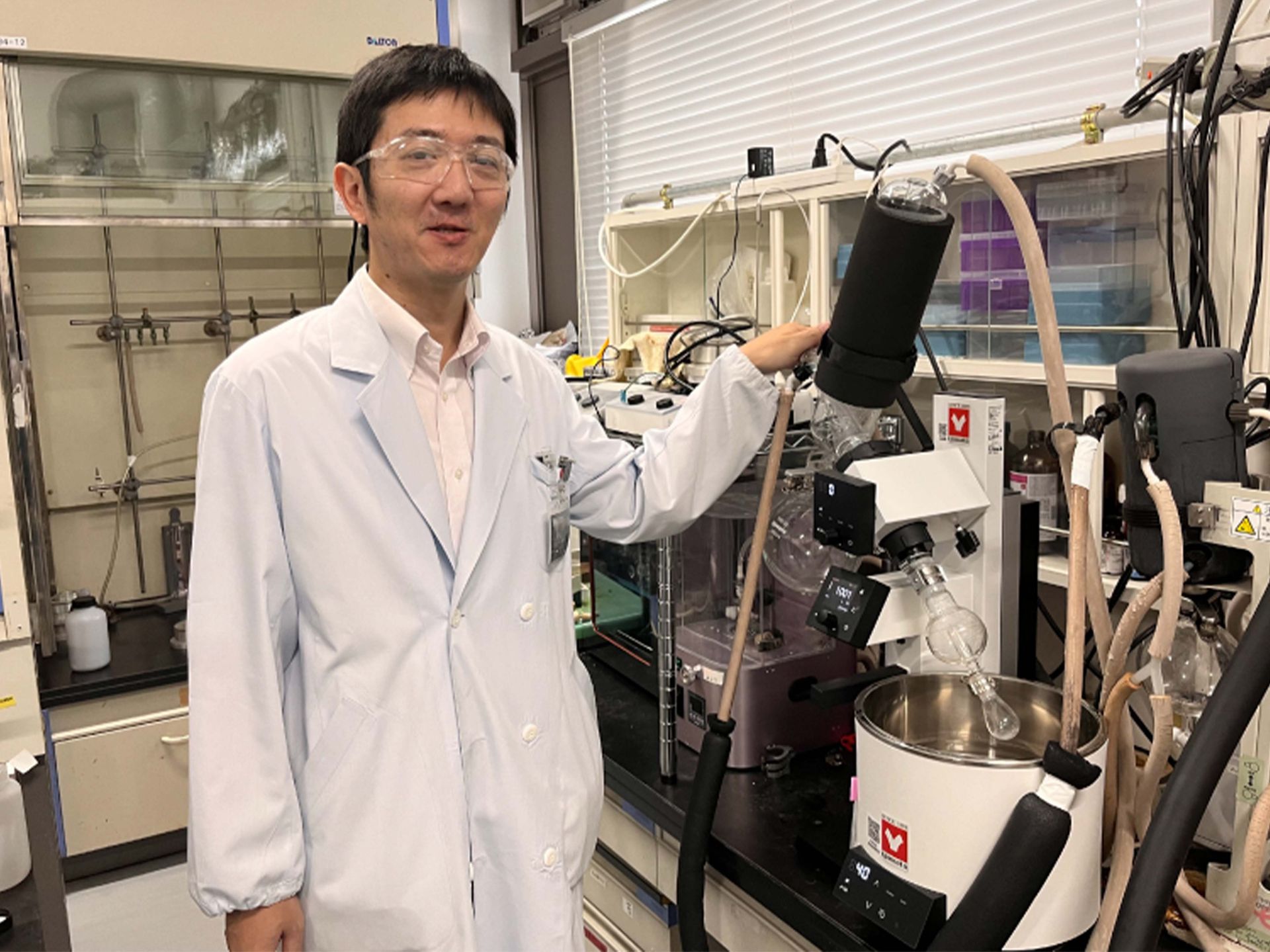

Dr Masato Takeuchi

Smooth evaporation with vacuum controller

Rotary evaporators equipped with vacuum controllers address the core issue of bumping. These devices significantly reduce or eliminate the likelihood of bumping by regulating the pump speed.

Users can set target pressure on the Yamato’s VR102S Vacuum Controller and walk away.

The vacuum controller manages pressure reduction in an automated system by first determining the starting pressure and then calculating the optimized duration for decreasing pressure to the preset target.

Faster solvent removal and more walkaway time with a vacuum controller.

This automated feature allows users to maximize evaporation speed without bumping.

Here's what our users have to say:

“I can easily adjust the vacuum level to the target pressure and achieve excellent yields with Yamato’s Vacuum Controller.

This significantly boosts our lab efficiency, as our operators can focus on other tasks while the rotary evaporator operates without worrying about bumping.”

Professor Eiko Sugiyama

Professor Eiko Sugiyama. Dept. Food & Health Sciences. The University of Nagano, Japan

No bumps on your road to more lab efficiency

Automation offers the ideal solution to bumping during distillation. Our rotary evaporator with vacuum controller supports precise automatic pressure control for evaporation, ensuring smooth and efficient operations.

From a customer’s perspective:

“With the vacuum controller that comes with the REV rotary evaporator set, internal pressure is adjusted automatically to optimize the drying process. This helped us cut the solvent evaporating time by 50%.

Not only does this speed up our workflow, the Yamato rotary evaporator gives us higher reproducibility in the physical properties of our samples.”

Dr Masato Takeuchi

Dr Masato Takeuchi with Yamato REV202M Rotary Evaporator with Vacuum Controller

Reliable equipment for frugal labs

Despite the improved yield and user experience, many labs still have their technicians tinkering with manual adjustments. Do you work in one of those labs with budgetary constraints?

Here’s the good news: the Yamato rotary evaporator is priced 10–20% lower than comparable models with similar features.

The REV202M is purpose-built for R&D with the widest range of rotation speed (5 – 315 rpms) than any other rotary evaporator on the market, so you can test more SOPs and develop better methods.

The ultimate rotary evaporator for R&D with the widest range of rotation speed and automated vacuum pump control

Yamato rotary evaporators also come with a rugged built and simple, intuitive interface.

Hear it from our customers in research institutes:

“Our lab has used many evaporators from various manufacturers over the years, but we’ve now replaced most of them with Yamato rotary evaporators, mainly because they are so durable and simple to use.

I even spilled solvent on the rotary evaporator once, which got to the base. The paint remained intact, and the machine functions flawlessly after a simple clean-up.”

Professor Toyonobu Usuki

Professor Toyonobu Usuki. Dept. Material & Life Sciences. Sophia University, Japan

You can now order rotary evaporators from Yamato directly. Or chat with our product specialists to find the model that is right for your application.

Order Now