| Type |

Upper / middle / lower stage pressure jet type rotary jet nozzle |

| Objects to be washed |

Glassware as a whole including test tubes, flasks, beakers (excluding pipet) |

| Detergent |

Liquid detergent/supplied by automatic supply unit

Powder detergent/manually supplied during operation

|

| Performance |

Operation panel |

Touch panel 4.3 inch LCD |

| Washing program |

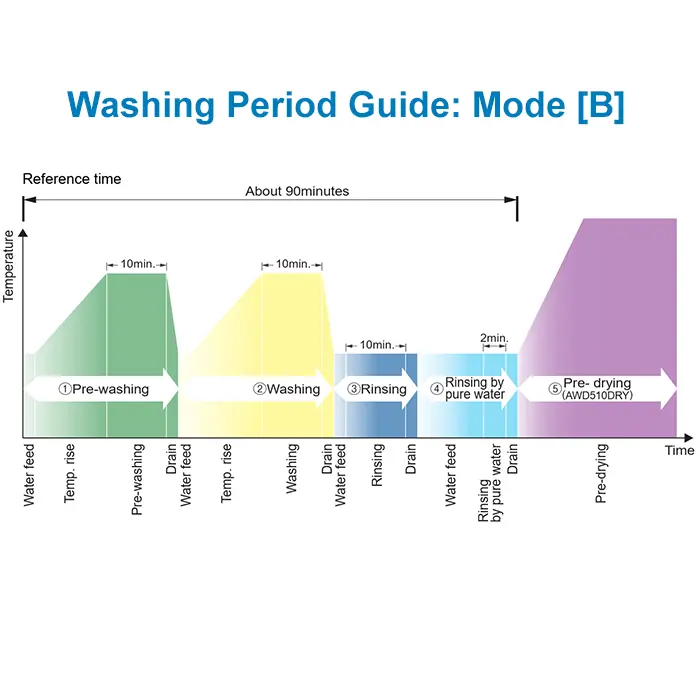

Pre-wash -> wash -> rinse -> final wash |

Pre-wash -> wash -> rinse -> final wash -> pre-drying |

Arbitrary selection of the

process |

Washing temperature setting: OFF, pre-wash and wash: 45~80°C,

rinse and final wash: 45~93°C

|

Washing temperature setting: OFF, pre-wash and wash: 45~80°C, rinse and final wash: 45~93°C,

pre-drying: fixed at about 60°C

|

| Washing time |

1~60 minutes (~10 minutes for 90°C or more), Wait,

Repeat count:1~10

|

1~60 minutes (~10 minutes for 90°C or more), Wait,

Repeat count:1~10, Pre-drying process: Time setting: 1~360 min, Wait OFF, Repeat count: 1

|

| Program |

Nine patters of above program can be stored |

| Process display |

Operation panel LED ON for each process pre-wash, wash, rinse, final wash, predrying: green

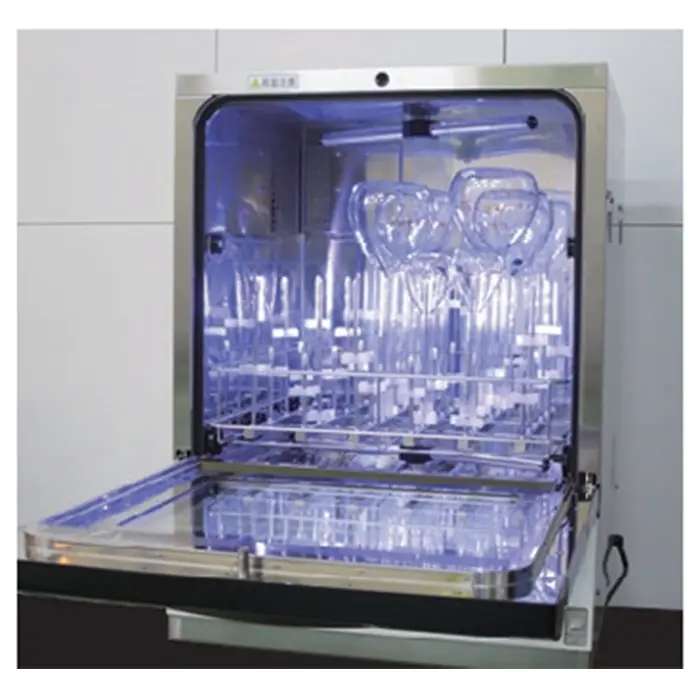

Lighting color inside the bath: Pre-wash [green], wash [yellow], rinse [blue], final wash [light blue], predrying [purple]

|

Maximum washing

volume |

With two stages: Upper stage 10kg (effective height 150mm), lower stage 15kg (effective height 165mm)

With one stage: Lower stage 15kg (effective height 300mm) with optional one-stage rack used

|

| Installation |

Ambient environment |

Operating ambient temperature: 5~40°C, Humidity 65±20%RH (no dewing), Elevation: 1500m or less above sea level

|

| Water supply conditions |

Tap water (mandatory): G3/4 connections (G1/2 on the equipment side), flow 10L/min or more, temperature: 5~25°C

Feed water pressure: 0.1~0.5MPa

Hot water (optional): G3/4 connection port (G1/2 on the equipment side), flow 10L/min or more, temperature: 5~60°C

Feed water pressure: 0.1~0.5MPa

Pure water (optional): φ10.5mm connection port, gravity water supply, temperature: 5~60°C

Feed water pressure: 0.02~0.1MPa

Feedwater rate: 11L

|

| Draining |

Temperature: 60°C or less, φ31.5mm connection port,on the equipment side: nominal 40 (40A) piping

Forced drain with pump

|

| Overflow |

Connection port 13mm |

| Composition |

Legs |

Level adjuster (M10 screw)

|

| Exterior |

Overall dimensions: W580×D600×H845mm (excluding protrusions)

Side/top surfaces: SUS304 hairline,bottom plate/backside: SUS304 2B

Front panel (front below): SPCC

|

| Door |

Front loading type (damper mechanism)

Double glass inside structure (heat-resistant reinforced),Outside: Polycarbonate

Operation panel (door upper portion); ABS Resin

|

| Inner tank |

Washing tank dimensions: W500×D480×H480mm (excluding protrusions), material: SUS316

Rotary nozzle shower type, internal filter 10 mesh, water tank filter 40 mesh, heater 2kW

Bathy internal temperature sensor (Pt100)

|

| Pre-drying unit |

|

Heater 700W, hot air drying with external air introduced via HEPA |

| Heat insulation material |

Melamine resin |

| Main power switch |

Leakage breaker function with overcurrent (provided in the front panel (lower front)) |

| Standby power switch |

Tact switch (provided in the right side of panel) |

| Steam cooling function |

Reduction of the steam amount due to steam cooling |

| Controller |

Calendar function (battery backup), set memory function |

| Safety device |

Interlock, overcurrent/sensitivity current, door lock, overtemperature prevention, water full detection,

circulation water pressure drop detection, leakage detection, prevention of water overtemperature

|

| Standard |

No. of rack stages |

2 or 1 (option) |

| Power supply |

Single phase AC220V 13A (breaker capacity 15A), Power cord: 3m, 3 wires. Round terminal for M5

|

| Internal dimension |

500×480×480 mm (WxDxH) |

| External dimension |

580×600×845 mm (WxDxH) |

| Weight |

Dry weight 87kg (excluding racks and circulation water) |

| Accessories |

Water supply hose [20A(G3/4) female - 15A(G1/2) female] 1.5m (2 pieces),

Drain hose (inside dia. 31×2m), Detergent bottle housing rack, detergent tube, operation manual,

cover to be used after removal of upper rack, overflow hose (inside dia. φ12×1.5m),

upper and lower rotation nozzles

|