Yamato DL410 Large Capacity Spray Dryer

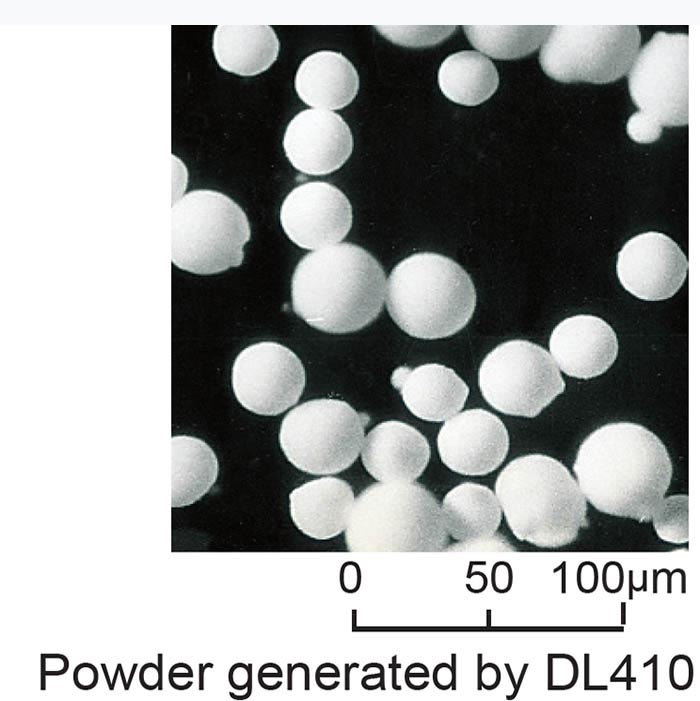

Yamato’s DL410 large capacity spray dryer produces fine particles from 1 to 100μm, which is considered to be extremely difficult to produce in laboratories. This spray dryer does not require samples to undergo pre or post processing such as filtration, separation, or pulverization. Furthermore, the spray dryer ensures efficient and quick drying of small, expensive, and heat sensitive samples with its easy operation.

Our DL410 spray dryer is useful for preliminary tests for pilot plant or expensive samples, micro capture spray drying research, as a substitute for general laboratory drying methods, and much more. Organic solvents are also supported with the attachment of GAS410 organic solvent recovery unit.

Spray dryer DL410 in food and beverage

Application: Emulsions

User Insights:

Why Customers Choose Yamato?

“We selected this spray dryer over other options because 90% yield could be achieved at a

price significantly cheaper that other similarly sized spray dryers.

The equipment additionally had a much shorter lead time (3 weeks) than any other manufacturer.

Additionally, one of the benefits other users might not think about until after purchasing is that the operator can see the nozzle spray in the main chamber.

Here’s exactly what helped us achieve our goals:

- Dryer design leads to optimal yields (product pulled from the bottom of the main chamber as opposed to outlet arm)

- Evaporation capacity sized appropriately to our formulation’s total solids content

- Ability to spray dry a formulation that contains a solvent

- Cyclone optimally sized for target particle size and yields

- Small footprint”

Why does this user recommend Yamato spray dryers?

“The dryer design is optimal. It allows us to achieve above average yields for spray drying. And Yamato’s customer service over the past 2 years has been excellent. Any questions have been answered in detail by Yamato’s technical service within 24 hours (usually much

quicker). Their reps are very thorough when troubleshooting issues and offer to work

with customers over video chat.”

Spray dryer DL410 in metals, minerals & mining

Application: Amorphous silica production

User Insights:

Why Customers Choose Yamato?

“We were looking for a product to produce zinc sulfate mono hydrate powder from aqueous (non-organic solvent) solution containing about 0.5 kg zinc sulfate per liter. Wanted to produce about 5 kg per day (~10 L/day solution) with particle size of at least 100 microns. Wanted to run the unit 24 hours a day.”

“For us, the best feature might be the needle knocker/nozzle blower which can allow many hours of run time without cleaning. We installed a custom 5L collection jar equipped with band heater that allows us to spray dry 1kg at a time without the need to cool the unit and empty the jar. So the ability to run for a long time without cleaning is very valuable.”

Why does this user recommend Yamato spray dryers?

“I recommend this product because the unit is reliable, and customer service is good.”

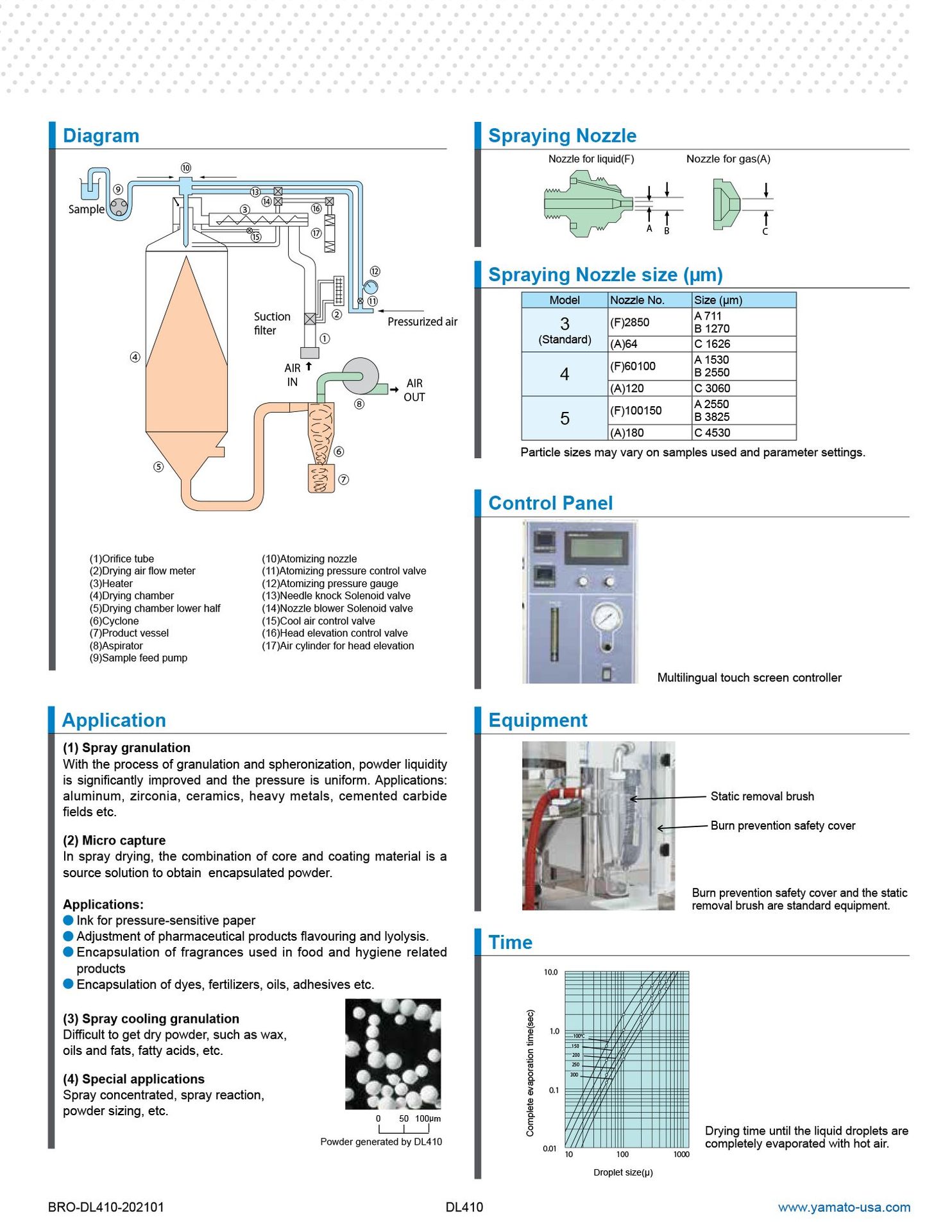

DL410

Features

- Liquid sample or solution is not required to undergo any pre or post processes such as filtration, separation, or pulverization

- Small, expensive and/or heat sensitive samples can be dried quickly and efficiently

- Processes samples as small as 0.5g of solid matter

- Safe for heat-sensitive samples, such as food or medical products

- No risk of contamination within the spray dryer

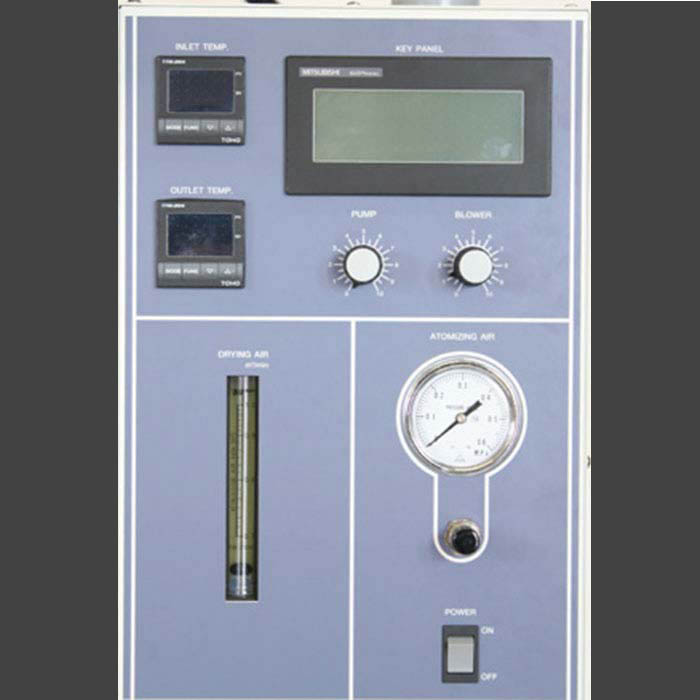

- Digital display of inlet/outlet temperature and drying air volume

- Detachable drying chamber, cyclone and product vessel

- Fast and easy clean up

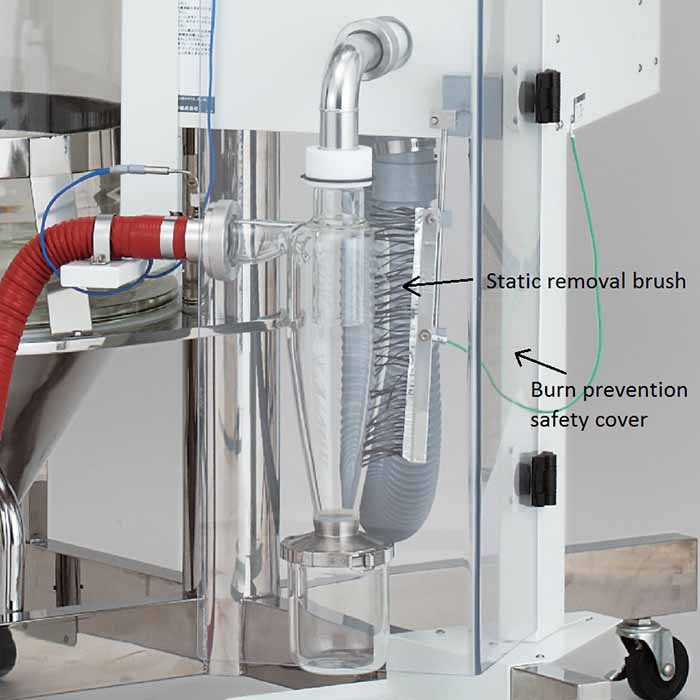

- The hot air inlet and drying chamber cover automatically move up and down, and since the cyclone and product vessel can easily be removed, cleaning and maintenance of the spray dryer after experiment is easy

- Control functions are conveniently arranged on the control panel for various conditions

- Temperature recorder, air flow meter, pressure gauge and other measurements allow easy control of experiment conditions

- Universal power supply and multi-lingual touch screen controller

Can your sample/solution be spray dried successfully?

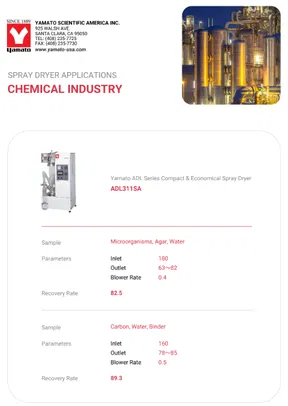

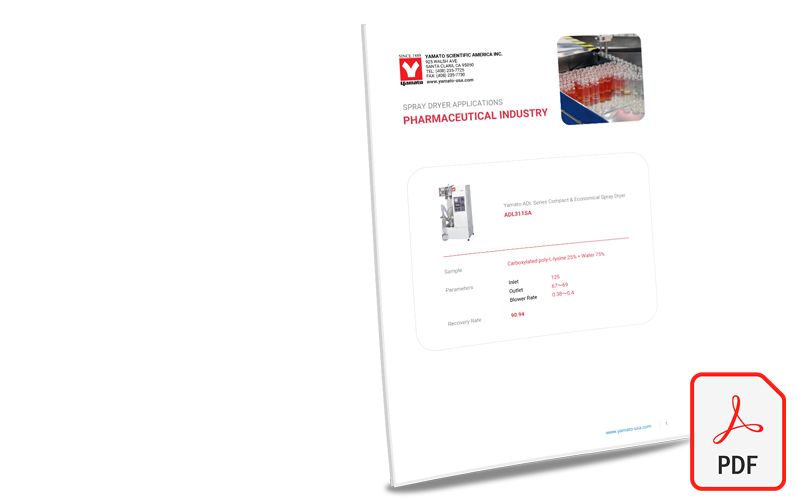

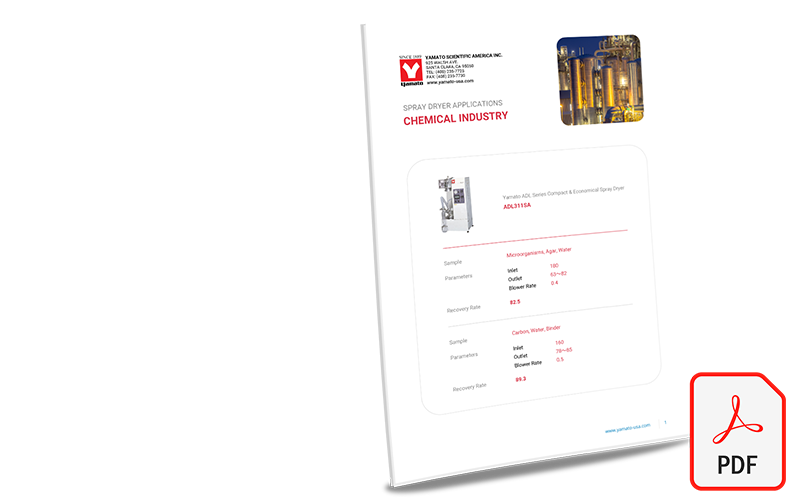

Here’s a quick reference for sample types and the parameters used to successfully spray dry them. These are real, verified samples used in labs today.