Plasma treating is low-cost, easy to do, and safer for operators than the alternative.

Learn how to find the best mix of features for your application in this guide.

At first, “plasma treater” sounds like something out of Blade Runner. But outside the movies, plasma treating is an incredibly effective, cost-saving way to clean and prepare surfaces for your application. The quality of the bond on a plasma-treated surface is often transformative for applications that previously relied on chemical surface cleaning.

It involves the use of ionized gas - plasma - to interact with a surface, removing contamination at a molecular level. We’re talking about atomic cleanliness, a term that might just impress your family when you explain it over dinner. No big deal, just working with plasma and achieving atomic cleanliness that no other process can match. Really, no big deal.

In plasma treatment, gas (typically air, oxygen, argon, or a combination) gets energized into a plasma state - a kind of fourth state of matter beyond solid, liquid, and gas. This energized plasma isn’t just about removing contaminants; it’s like a team of tiny, super-charged engineers that modify the surface properties of your materials, making them more adhesive, receptive to coatings, or optimized for bonding - all without the need for solvents or messy chemicals.

That’s why plasma treatment is often chosen over other methods - it’s efficient, eco-friendly, and improves surface functionality.

Plasma treaters don’t just tackle the obvious challenges. Sure, they can remove surface contaminants like residues and oils, but their real strength is in enhancing surface energy. Plasma treatment alters the chemical makeup of the surface to create better adhesion for coatings, bonding materials, or inks. And plasma doesn’t care if the surface is rough, smooth, porous, or even heat-sensitive - it can activate all kinds of surfaces without damaging the underlying material.

That’s why plasma treatment is a go-to technology in industries like automotive, medical devices, and packaging. From preparing materials for bonding in electronics to improving adhesion in packaging and printing, plasma treatment offers unmatched versatility in surface preparation.

So, can this transform your workflow?

Whether you’re dealing with polymers, metals, glass, ceramics, or something else entirely, there’s a good chance your surfaces will perform better with a plasma surface treatment.

Plasma treatment and plasma cleaning are different things.

And it’s easy to tell the difference between equipment used for one or the other.

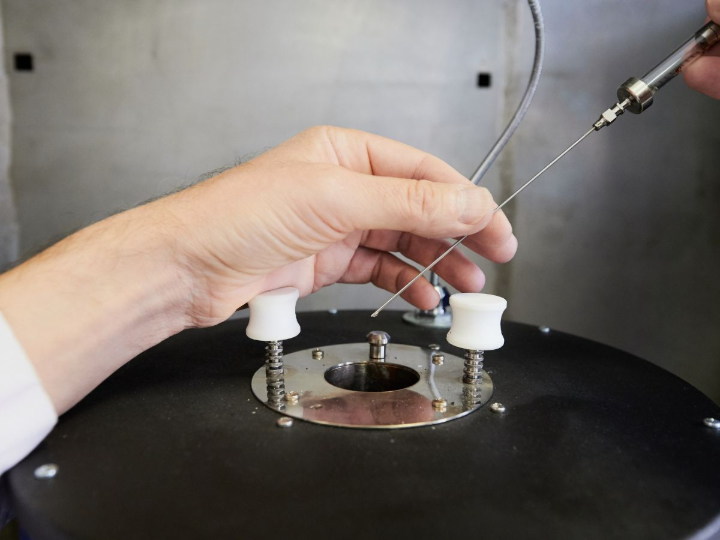

Plasma treatment is generally done

in an “atmospheric” setting, with nozzles.

Plasma cleaning generally involves a chambered instrument that looks like an oven.

And there are some other key differences to know about before talking to a sales rep.

Continuous processing

Atmospheric plasma is ideal for continuous processing, where surfaces are treated as part of a moving production line.

It allows for large-scale treatments without the need to stop the process to load and unload materials into a chamber.

Chambered plasma is more suitable for batch processing, where each part or group of parts is treated separately in a controlled vacuum environment.

Speed and flexibility

Atmospheric plasma is faster and more flexible for treating larger or complex surfaces, and it’s easier to integrate into existing production lines.

It’s typically used in industries like automotive, packaging, printing, and textiles, where surface modification (like improving adhesion for inks or coatings) is needed at high speeds.

Chambered plasma provides precise control over the environment, which is often needed for delicate, high-precision, low-volume applications like semiconductor or medical device R&D.

Gas control

In atmospheric plasma treatment, gases are exposed to open air, so the environment is less controlled compared to a vacuum.

However, it's still highly effective for modifying surface properties, such as increasing wettability or adhesion.

In Chambered plasma, the vacuum allows for precise control of gas composition and pressure, which may be necessary for more sensitive materials.

How does atmospheric plasma surface activation (treatment) work?

Atmospheric plasma treatment is a simple, effective process, but unlike traditional chambered systems, it doesn’t require a vacuum. This allows the treatment to happen in an open-air environment, making it ideal for continuous production lines where you need to treat large surfaces or keep things moving without the need to stop and load materials into a chamber.

The process in a nutshell

Ionized Gas

In atmospheric plasma treatment, a gas (typically air, oxygen, nitrogen, or a mix of gases) is energized using high voltage, creating plasma. This plasma is full of reactive ions, electrons, and radicals, which are applied directly to the surface through a nozzle or jet. The plasma immediately begins interacting with the surface, altering its properties to improve adhesion, wettability, or bonding potential.

Surface Interaction

As the reactive particles in the plasma interact with the surface, they introduce new chemical groups or remove barriers like low-energy surface layers. This activation enhances the surface’s ability to bond with coatings, inks, or adhesives, making the material more receptive to further treatment.

The Need for Speed

Since there’s no need for a vacuum chamber, the process is continuous and fast. Surfaces can be treated as they move through a production line, making atmospheric plasma treatment a great fit for industries like automotive, packaging, or electronics, where speed and flexibility are key. The treatment is all-dry, meaning there’s no need to deal with chemical solvents or residue.

There are 4 primary types of atmospheric plasma treatment.

Generally, each type achieves the same outcome. But there may be subtle differences in the quality of that outcome based on the materials in your application.

Air-based atmospheric plasma

Air (a mix of nitrogen and oxygen) is ionized, producing a cost-effective and eco-friendly plasma source. It’s widely used in industrial processes.

Ideal For: Surface activation for wettability, printing, and adhesion.

Result: Improved adhesion and surface energy, especially for materials like plastics, metals, and glass.

Oxygen-based atmospheric plasma (O₂)

To add a fourth column, reduce the size of these three columns using the right icon of each block. Then, duplicate one of the columns to create a new one as a copy.

Ideal For: Improving adhesion, surface activation for bonding and coatings.

Result: Increased surface energy, improved adhesion for coatings, paints, and adhesives.

Nitrogen-based atmospheric plasma (N₂)

Nitrogen plasma introduces amine groups to the surface, which improves adhesion and bonding strength, especially with polymers.

Ideal For: Surface activation of polymers and plastics for better bonding or printing.

Result: Stronger chemical bonding to coatings or adhesives, enhanced wettability.

Argon-based atmospheric plasma (Ar)

Argon plasma provides a non-reactive, physical cleaning effect by bombarding the surface without chemically altering it. It’s often used with other gases.

Ideal For: Gentle cleaning of delicate surfaces, or in combination with reactive gases for surface activation.

Result: Physical removal of contaminants, surface modification without chemical interaction.

What are the primary types of chambered plasma cleaning?

There are 3 main types of chambered plasma cleaning.

This is how plasma cleaning adjusts based on your needs - whether you’re dealing with stubborn organic matter or delicate metals, there’s a plasma process that fits the bill.

What’s going on at the molecular level?

Plasma surface activation works by interacting with the molecules on your material’s surface. Take oxygen plasma, for example. It’s all about the chemistry.

The oxygen atoms react with carbon-based contaminants, breaking the bonds that hold them to the surface and converting them into gases like carbon dioxide (CO₂). These gases are then whisked away, leaving the surface pristine.

Ablation

The contaminants are physically bombarded and broken apart.

Activation

The plasma introduces reactive groups to the surface, increasing its wettability (which is essential for adhesion).

Cross-linking

This strengthens the molecular bonds on the surface, making it more durable.

How to choose a plasma treater?

That educational info is all well and good, but now comes the tricky part. How do you settle on the most appropriate plasma surface activation equipment for your application? Here are the key factors to consider when choosing a plasma cleaner:

1. Type of plasma instrument: chambered vs. atmospheric

Plasma cleaners/treaters come in two main flavors, which you read about above: chambered (low-pressure) and atmospheric (you get it).

Chambered Plasma Cleaners

Chambered Plasma Cleaners

operate in a vacuum chamber and are good when dealing with delicate materials (like polymers or sensitive electronics). Low-pressure systems are highly controlled, giving you high repeatability under extremely tight constraints. These lend themselves to more uncommon, niche applications.

Atmospheric Plasma Cleaners

Atmospheric Plasma Cleaners

are suitable for continuous processes or larger surfaces, such as in production lines. No vacuum chamber is needed here, so these cleaners are often used for industrial settings or academic settings where they’re used more than a few times in a week.

How to decide

If you’re in a low throughout lab setting or handling uniquely small, sensitive components, your work may be more suitable for a chambered plasma cleaner. In most other scenarios, from larger-scale manufacturing to high-volume academic research, atmospheric might be the better choice.

2. What materials are you treating?

Different materials respond to plasma treatment in different ways. Whether you’re treating metals, polymers, glass, or composites, you’ll want to make sure your plasma treater can handle the material.

For polymers: Plasma treating can improve surface adhesion by introducing functional groups that make the surface more "sticky" for bonding or coatings.

For metals:

You’ll want to remove oxides or organic contaminants to get a clean, bare surface. Hydrogen-based plasma treaters are ideal for this.

For glass or ceramics: Plasma treatment can remove residues and improve adhesion without affecting the material's integrity.

How to decide

Match your plasma treater to the materials you work with most often. Ask your supplier about what gases and settings are ideal for your specific applications.

3. Chamber size and gas options

If you think your niche application requires a chambered option, the size of the chamber and the gases you use will depend heavily on your application.

- Chamber size (more on chamber size in the next chapter)

Smaller chambers are more energy efficient and suitable for research labs handling small samples. Larger chambers obviously handle larger volumes of sample or larger samples. - Gas compatibility

Not all plasma cleaners are built to use the same gases. Some accommodate multiple gases (like oxygen, argon, hydrogen), while others do not. If your work requires versatility (say, cleaning different materials that require different gases), make sure your plasma cleaner is compatible with a variety of gases. (See the tables from sections 3 and 4 4).

How to decide

Consider both the size of the parts you’ll be cleaning and the gases you’ll need. Opt for a system with flexibility if you’re working with different types of materials and cleaning requirements.

4. Safety features

There are 6 primary safety angles to look at with your plasma treater.

Electrical safety

Plasma treaters deal in high voltage. Don’t let your cats chew the power cables.

Gas safety

Gas flow monitors should be simple and the shutoff valve should be accessible.

Operator safety

Your supplier should provide training to operators so rookie mistakes are kept to a minimum.

System monitoring and alarms

Temperature and pressure should be automatically monitored. An alarm should sound, or the system should shut down, if the thresholds are passed.

Environmental safety

Depending on the gas used, you might need an upgrade to your workplace’s ventilation.

Cooling systems

Plasma treaters generate heat, especially in continuous-use scenarios. Cooling systems are used in 90% of applications.

How to decide

Don’t compromise on safety. Make sure any plasma treater you consider has robust safety mechanisms in place, especially if you’re working with reactive gases or high-energy systems.

5. Maintenance requirements

Plasma treatment machines, like any instrument, require regular maintenance. Take maintenance seriously, because scheduled downtime is 10X less expensive than surprise downtime.

Below is a general guide for maintenance. Your manufacturer will always have more accurate maintenance information.

Your atmospheric plasma treater purchase decision matrix.

If you need a plasma cleaner, what size chamber do you need?

When choosing a plasma cleaner, the size of the chamber is a big part of your decision. It determines the types and sizes of materials you can clean at once, as well as how efficiently the system will operate in your specific environment.

It also sets limits on your future applications. If you choose too small, you won’t be able to scale your work up easily in the future. But a larger chamber comes at a cost today, and you might not have the available budget.

So it’s a balancing act.

1. Small chambers for precision and research applications

Small chambers are commonly used in R&D environments where precision is critical. These chambers are used for R&D applications involving small parts, like:

- Printed circuit boards (PCBs)

- Medical devices and implants

- Optical components (e.g., lenses, mirrors)

- Microfluidic devices

Advantages

- Small chambers use less gas and require less energy to maintain the plasma, making them cost-effective and energy-efficient.

- With a smaller volume, it's easier to control the plasma and maintain uniform conditions, ensuring precise cleaning results. This is especially important for delicate or sensitive parts.

- A smaller chamber means shorter cycle times, as it’s faster to evacuate air and reach the necessary vacuum pressure.

Disadvantages

- Small chambers use less gas and require less energy to maintain the plasma, making them cost-effective and energy-efficient.

- With a smaller volume, it's easier to control the plasma and maintain uniform conditions, ensuring precise cleaning results. This is especially important for delicate or sensitive parts.

- A smaller chamber means shorter cycle times, as it’s faster to evacuate air and reach the necessary vacuum pressure.

In general, labs handling small, precise components, R&D settings where energy efficiency and precision are key, and applications where the parts cleaned need a high degree of uniformity and control should consider smaller chamber sizes.

2. Medium chambers for versatility and flexibility

Medium-sized chambers are a middle ground, offering versatility. These are often found in mid-scale manufacturing settings where there’s a need to process a range of part sizes but still maintain some level of precision.

Advantages

- Medium chambers provide enough room to handle a variety of part sizes, from small electronic components to mid-sized medical devices, without compromising the precision of the cleaning process.

- You can clean more parts per cycle compared to small chambers, which makes it ideal for labs or production lines that need a balance between volume and precision.

- With the ability to handle a range of part sizes, these chambers are adaptable to different projects or product lines.

Disadvantages

- Medium chambers consume more gas and energy compared to small chambers, though not as much as larger models.

- Because the chamber is bigger, it may take longer to reach the desired vacuum pressure, which can slightly extend the cleaning process.

In general, medium sized chambers are suitable for companies handling both small and mid-sized components across various industries (e.g., electronics, automotive, medical devices), as well as labs that need a versatile tool to accommodate a range of materials and parts sizes, and organizations scaling up production but still requiring a high level of precision.

3. Large chambers for high throughput

Large chambers are designed for large parts (surprise!). These systems are typically found in automotive, aerospace, or electronics manufacturing, quality control, and R&D settings.

Advantages

- Large chambers can process multiple parts, batches, or large components

- If you're dealing with large objects (e.g., automotive parts, large glass panels), a large chamber is essential to clean evenly across the entire suface.

- Large chambers are designed for continuous operation, reducing downtime for refilling gas or maintenance.

Disadvantages

- There are still size and throughput limitations due to the chamber.

- For large parts, a plasma treater may be more economical than a chambered plasma cleaner.

In general, large plasma cleaners are niche instruments that can often be replaced by plasma treater machines.

4. Batch vs. continuous processing

Another factor to consider with chamber size is whether your process will be batch-based or continuous.

Batch processing

Typically, smaller to medium chambers are used for batch processing. You load a set of parts, run the cleaning cycle, and then load a new batch. Batch systems are more precise but have limited throughput.

Disadvantages

Chambered plasma cleaners aren’t recommended for continuous processing. If this is your goal, we recommend learning about plasma treaters.

Your Chamber Size Decision Matrix

Industry-specific applications of plasma treatment

Plasma treatment is common across many industries. For delicate electronics, medical devices, or automotive components, plasma treatment can improve adhesion, cleanliness, and surface preparation.

How are your colleagues and competitors at different organizations using it

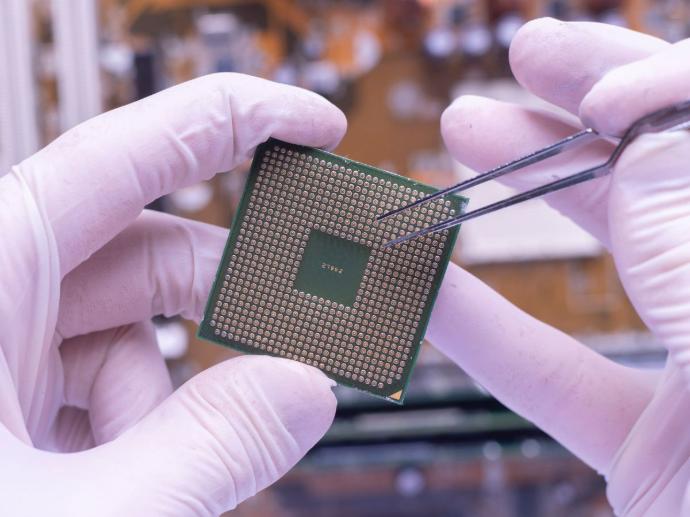

In electronics manufacturing

Plasma treatment is widely used in electronics to activate surfaces and improve adhesion for coatings, solder masks, and bonding materials on printed circuit boards (PCBs). The plasma increases the surface energy of electronic components, ensuring better bonding without adding heat to sensitive parts.

- Improved solder mask adhesion

Atmospheric plasma treatment increases the surface energy of PCBs, allowing solder masks and coatings to adhere more effectively. This results in more reliable and durable connections for high-performance electronics. - Enhanced wettability

By modifying the surface with plasma, wettability improves, which ensures that inks, coatings, and adhesives spread evenly across the surface without beading or running. Companies like Intel and Samsung use plasma treaters in semiconductor production to prepare surfaces for bonding. The increased surface energy ensures stronger connections for components that need to perform under stress and heat.

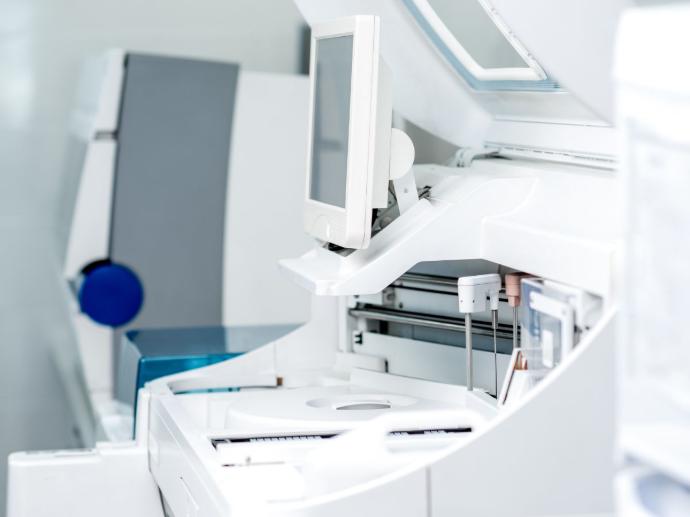

In medical device manufacturing

Medical devices often require biocompatible surfaces that can safely interact with human tissues or fluids. Plasma treatment prepares these surfaces for adhesion, coating, or sterilization without using harmful chemicals or solvents.

- Stronger adhesion for coatings

Plasma treatment ensures that coatings like hydrophilic layers on catheters or implants adhere securely to the surface, reducing friction and improving the functionality of medical devices during insertion or use. - Surface activation for bonding

Plasma treaters activate surfaces to improve bonding strength in devices made of silicone, plastics, or metals. This ensures that medical implants or tools maintain their integrity during use. Companies like Medtronic and Abbott use atmospheric plasma treatment to prepare surfaces on catheters, improving the adhesion of hydrophilic coatings and ensuring that these devices perform reliably in clinical settings.

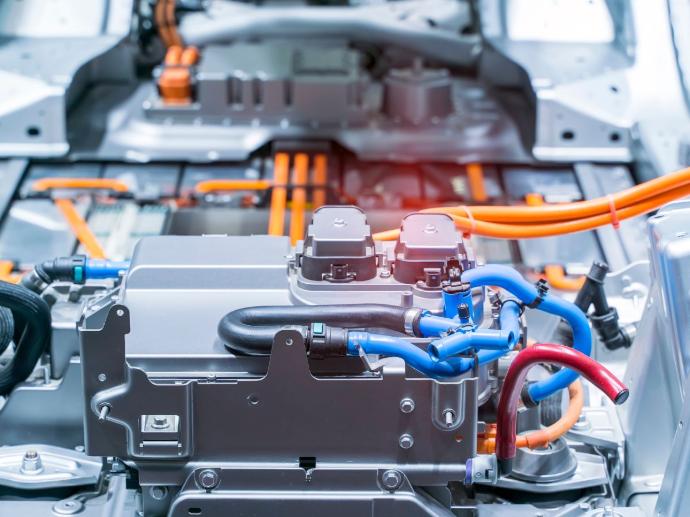

In the automotive industry

In automotive manufacturing, plasma treatment is essential for improving adhesion between different materials, such as plastics, glass, and metals. Plasma treaters help ensure that surfaces bond securely, even under extreme conditions like temperature fluctuations and vibration.

- Better bonding for adhesives

Plasma treaters increase the adhesion strength of materials, making them more receptive to glues and sealants. This ensures that windshields, body panels, and interior components stay securely bonded, even in challenging environments. - Improved durability of coatings

Plasma treatment ensures that paints and protective coatings adhere more effectively to automotive surfaces, improving their longevity and resistance to environmental factors such as heat, moisture, and corrosion.

Companies like BMW and Tesla rely on atmospheric plasma treaters to prepare glass surfaces before bonding them to car frames. This guarantees long-lasting bonds that withstand extreme temperature shifts and mechanical stress.

In the aerospace industry

In aerospace, components must withstand extreme environmental conditions, including high pressure, temperature fluctuations, and mechanical stress. Plasma treatment ensures that composite materials, metals, and adhesives bond securely, providing durability and safety.

- Improved composite bonding

Plasma treatment enhances the bonding of carbon fiber composites, which are critical to reducing the weight of aircraft while maintaining structural integrity. Plasma treatment ensures these composites bond strongly with adhesives used in assembly. - Surface preparation for critical components

Plasma treaters prepare sensitive surfaces, such as metals used in aircraft components, by increasing their surface energy, ensuring that coatings and adhesives adhere uniformly.

Boeing and Airbus use plasma treaters to prepare composite surfaces in aircraft assembly, ensuring strong, reliable bonds for components that must endure extreme conditions.

In textiles and consumer goods

Plasma treatment is also used in textiles to enhance the adhesion of coatings or dyes and improve product durability. In consumer goods, plasma treatment can improve the bonding of plastic or composite parts.

- Better coating adhesion for textiles

Plasma treatment increases the durability and performance of coatings used in textiles by ensuring they adhere more securely to the fibers, improving the longevity and wear resistance of fabrics. - Enhanced bonding for consumer goods

In products like electronics or household items, plasma treaters prepare surfaces made from plastic or composite materials, ensuring that parts bond securely and that coatings and paints adhere evenly.

Boeing and Airbus use plasma treaters to prepare composite surfaces in aircraft assembly, ensuring strong, reliable bonds for components that must endure extreme conditions.

In packaging and printing

In the packaging and printing industries, plasma treatment is used to activate surfaces for better adhesion of inks, adhesives, and coatings. This is critical for high-quality printing and labeling on difficult-to-bond materials like plastics and metals.

- Enhanced printability

Plasma treaters modify the surface energy of packaging materials, ensuring that inks and dyes adhere properly and last longer, even on non-porous surfaces. - Better adhesion for labels

Plasma treatment ensures that labels and seals bond securely to packaging materials, preventing peeling or failure during handling and shipping.

Companies like Amcor and Tetra Pak use plasma treaters to prepare plastic films before printing, increasing surface energy and ensuring that inks adhere properly for high-quality, durable packaging.

Plasma cleaning is also used widely in

Optics: Plasma removes contaminants from optical glass and mirror surfaces.

Solar: As in semiconductors, plasma treatment removes contaminants from bond pads and conductive materials, ensuring improved conductivity and reliability.

Rubber processing: Plasma treatment can eliminate mold release agents and lubricants from rubber before gluing or bonding, ensuring a secure, long-lasting bond.

Are you working on a frontier application? Here’s where plasma is going.

As plasma technology continues to evolve, the future holds exciting possibilities for plasma treaters. From nanotechnology to additive manufacturing (3D printing), and the integration of plasma into smart manufacturing environments, new innovations are driving plasma treatment into new and more advanced application.

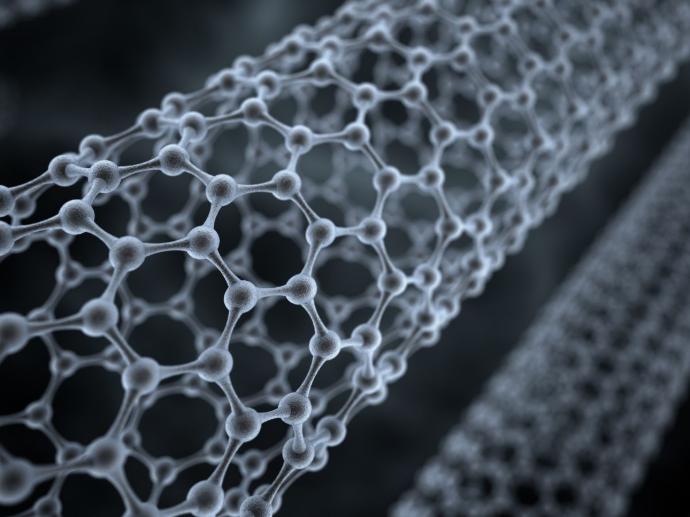

Plasma in nanotechnology

Nanotechnology involves manipulating matter on an atomic or molecular scale, and plasma treatment is being used to modify surfaces at the nanoscale. This has significant implications for industries like electronics, biomedicine, and materials science.

Precision surface modification

Plasma can modify surfaces down to the nanometer level, allowing for highly targeted activation of materials. This is crucial in fields like microelectronics, where components are shrinking and require surface modifications without bulk material changes.

Nanomaterials and coatings

Plasma treatment is playing a role in the development of nanomaterials, such as graphene or carbon nanotubes, by optimizing surface properties for integration into advanced products. Plasma can be used to deposit or remove nanoscale layers of material, creating superior functional coatings that enhance product durability, conductivity, or biocompatibility.

Medical nanotechnology

Plasma treatment is playing a role in the development of nanomaterials, such as graphene or carbon nanotubes, by optimizing surface properties for integration into advanced products. Plasma can be used to deposit or remove nanoscale layers of material, creating superior functional coatings that enhance product durability, conductivity, or biocompatibility.

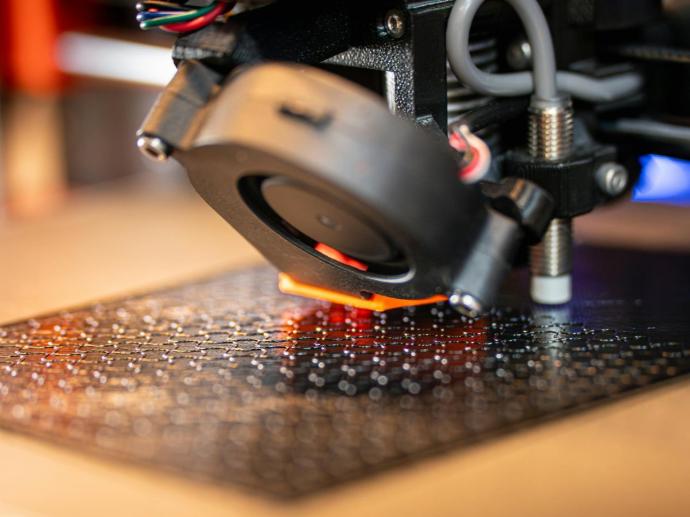

Additive manufacturing (3D printing)

Plasma treatment is beginning to integrate with additive manufacturing, commonly known as 3D printing. Plasma's ability to activate surfaces and improve adhesion is vital for creating layered structures that require strong bonding between printed materials.

Surface activation for 3D printing

In 3D printing, plasma treatment can prepare each layer of material before the next one is deposited, enhancing the bonding strength between layers. This leads to stronger, more durable printed objects, which is especially important for high-performance parts in industries like automotive and aerospace.

Post-processing of 3D printed parts

Plasma treatment is also being used in post-processing to improve the surface finish of 3D-printed objects. This includes modifying surface roughness, improving adhesion for coatings, and ensuring that the final product meets industry standards for durability and performance.

Bio-printing applications

In the realm of bio-printing, where tissues or organs are printed for medical use, plasma treatment helps ensure surfaces are biocompatible and that the layers of biological material bond securely.

Integration into smart manufacturing

Plasma treatment is beginning to integrate with additive manufacturing, commonly known as 3D printing. Plasma's ability to activate surfaces and improve adhesion is vital for creating layered structures that require strong bonding between printed materials.

IoT-enabled plasma systems

IoT connectivity is allowing plasma treaters to be more intelligent and connected. Bleeding edge systems can now monitor their own performance, collect data on gas usage, operational efficiency, and treatment outcomes, and provide real-time feedback to operators. This data can be used to optimize production lines, reduce downtime, and ensure consistent quality across large-scale operations.

Automation and robotics

Plasma treaters are being integrated into fully automated robotic production lines, where they can be used to treat surfaces without human intervention. Robots equipped with plasma nozzles can activate surfaces on parts as they move through the production line, providing precise, repeatable treatments that improve speed and quality.

Predictive maintenance

Smart plasma treaters will soon predict when maintenance is needed, reducing the risk of unexpected downtime. By tracking data like gas flow, nozzle wear, and plasma intensity, these systems will alert operators when it’s time to replace components or recalibrate, ensuring that production remains smooth and uninterrupted.

Sustainability and green manufacturing

As sustainability becomes a priority across industries, plasma treatment is seen as a key technology for green manufacturing. Because plasma treatment reduces or eliminates the need for harmful chemicals, it plays an essential role in environmentally friendly production processes.

Reduction of chemical waste

Plasma treatment continues to grow in industries looking to replace traditional chemical-based cleaning or activation processes. By reducing the use of solvents, acids, and other harmful chemicals, plasma treaters help companies meet environmental regulations and reduce their carbon footprint.

Energy-efficient systems

Ongoing innovations in plasma generation are focused on improving energy efficiency, reducing the amount of electricity needed to sustain plasma for long periods. This is critical for industries with high production volumes, such as automotive or packaging, where reducing energy use translates into significant cost savings and a reduced environmental impact.

That was a lot to read. What are you going to do next?

Talk to a few manufacturers about your application, collect quotes (starting with us right here), and be sure to ask about the long-term operational costs of your plasma treatment machine.

Good luck, and we hope the information in this guide helps you find the best plasma treatment instrument for your application.