Substrate manufacturers keep rolling out new materials with different machining and customization to match the demand in semiconductor applications for power devices.

How do chip manufacturers choose the most suitable substrates for their design?

What thermal data is the engineering team basing their material selection on?

Let’s take a closer look at the different kinds of popular choices for semiconductor substrates and the critical thermal data engineers need to improve thermal management.

Click here to download a comprehensive guide on substrate material thermal evaluation.

Technical ceramic, DCB ceramic, metallized ceramic, and how are they different from your coffee cup?

Why do we use ceramics as metallized substrates?

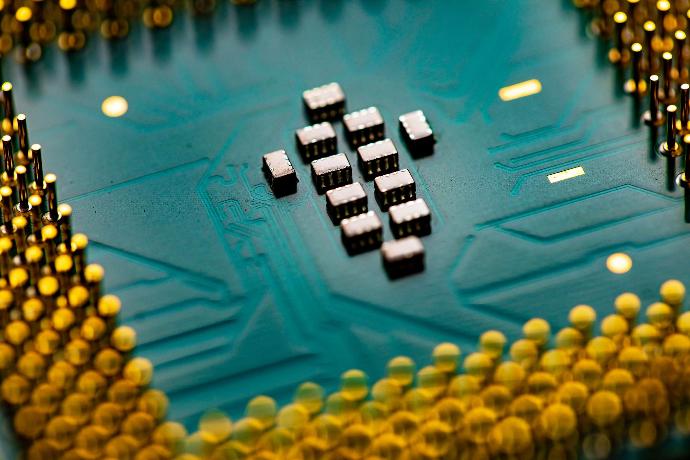

In power electronics, just like printed circuit boards, metallized substrates need to electrically connect components and help dissipate their heat. These metallized substrates must be capable of handling high currents and providing strong voltage isolation—sometimes up to several thousand volts. They also need to endure a wide temperature range, often up to 150 or 200°C.

Ceramics are preferred over metals and polymers for substrates because of their superior hardness, compressive strength, and resistance to wear, abrasion, chemicals, and electricity.

They also match well in terms of thermal expansion with other components of power modules.

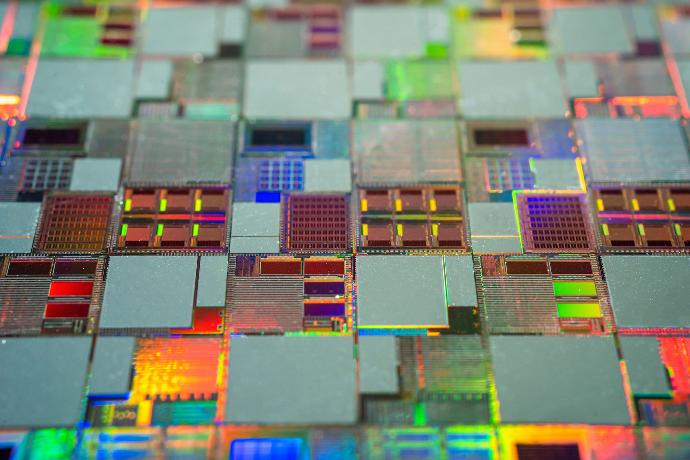

Semiconductor substrates require meticulous machining and modifications to meet the exact specifications needed for high performance power module applications.

Semiconductor substrates require meticulous machining and modifications to meet the exact specifications needed for high performance power module applications.Technical ceramic

Technical ceramics, also known as engineered or advanced ceramics, are a step up from the traditional ceramics, like your coffee mug, which is made from natural clays.

These high-performance ceramics are made from highly purified materials, refined to control particle size and shape, and then mixed with other materials to get the right properties. Once shaped, they're fired under strict conditions—sometimes in a vacuum or controlled atmospheres—to nail the specific qualities needed.

Often, they require a bit of extra machining after firing to meet the exact specifications needed for high-tech uses.

The choice between oxides (alumina), non-oxides (aluminum nitride and silicon nitride), or ceramic composites often comes down to the individual thermal conductivity and the cost of each material.

Considerations for choose insulating substrates include the material’s hardness, compressive strength, and resistance to wear, abrasion, chemicals, and electricity.

Considerations for choose insulating substrates include the material’s hardness, compressive strength, and resistance to wear, abrasion, chemicals, and electricity.From clay to super heat spreaders

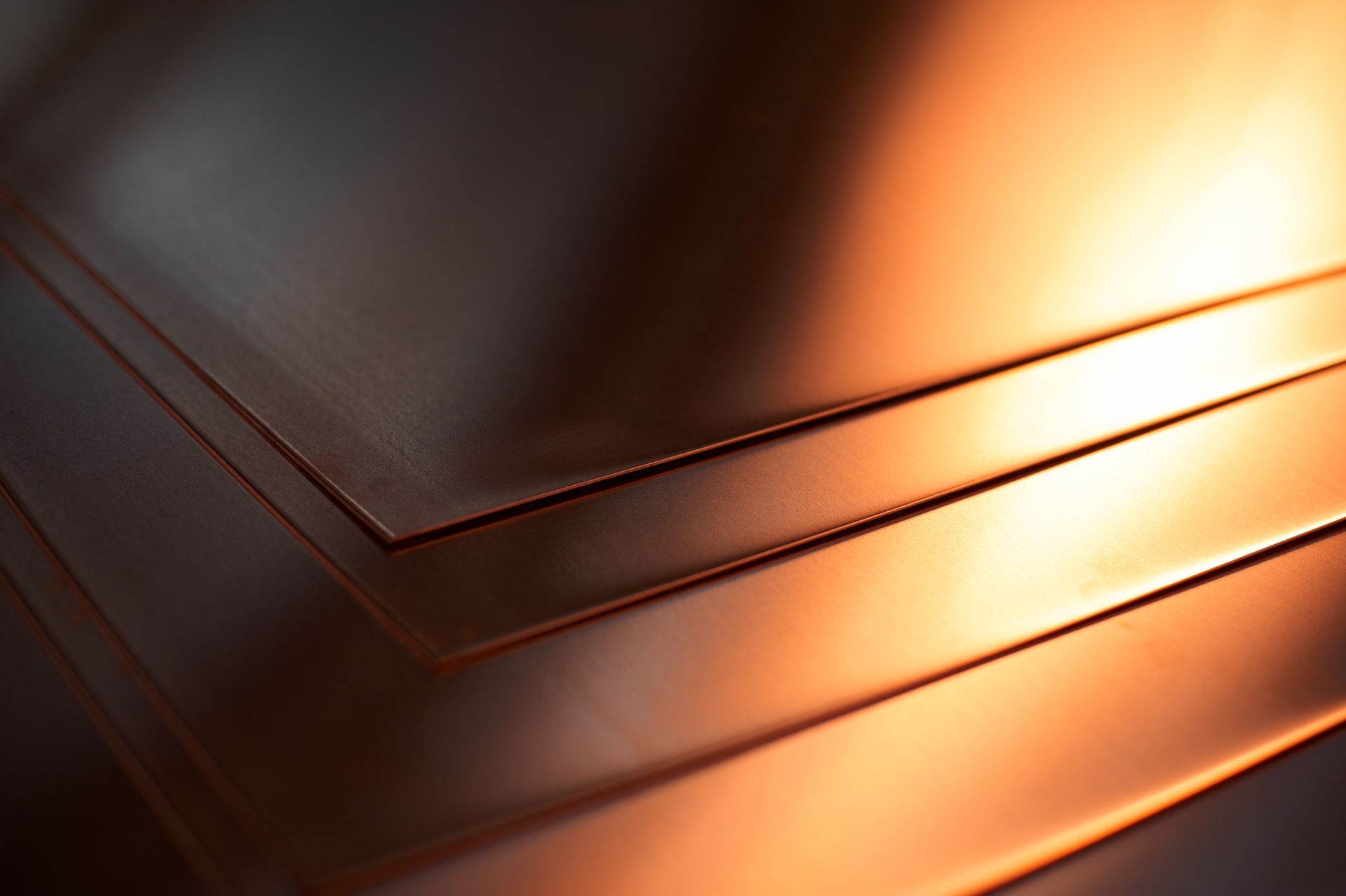

To bolster their roles as both electrical and thermal insulators in power modules, copper or aluminum are often added to technical ceramic to enhance their heat spreading capabilities.

Ceramics with direct copper bonding (DCB) are particularly popular in power modules for their superb electrical insulation and robust heat spreading abilities.

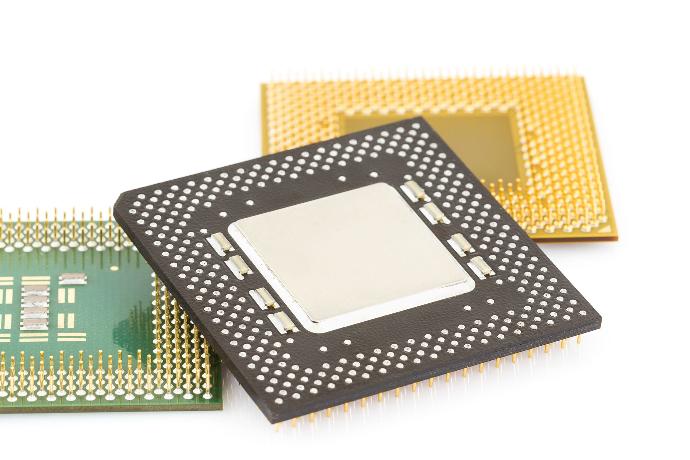

Common ceramic materials used in DCB include:

- Alumina (Al2O3): Low thermal conductivity, but popular for its cost-effectiveness.

- Aluminum nitride (AlN): Chosen for its superior thermal conductivity.

- Silicon nitride (SiN): Provides moderate thermal conductivity.

- HPS (Alumina with 9% ZrO2): Utilized for enhanced properties.

- Beryllium oxide (BeO): Noted for its high thermal conductivity, though its use is limited due to toxicity concerns.

Click here to download a comprehensive guide on substrate material thermal evaluation.

Metalized ceramics with direct copper bonding (DCB) are used in power modules for their superb electrical insulation and robust heat spreading abilities.

Metalized ceramics with direct copper bonding (DCB) are used in power modules for their superb electrical insulation and robust heat spreading abilities. Modeling inefficiency

In most production processes, thermal testing is done at the device level. With only standard data from material manufacturers, like maximum heat capacity, shock resistance, and thermal conductivity for electronic engineers to build their models.

This could lead to several issues:

- large margin to compensate for practical thermal values under real workload, which can compromise performance;

- a lengthy sign-off process might be needed to retest and possibly change materials during later production stages;

- or, the device could fail due to unresolved thermal issues.

Thermal resistance measurements improve thermal planning, which helps to reduce production scrap and lower the risk of product recall.

Thermal resistance measurements improve thermal planning, which helps to reduce production scrap and lower the risk of product recall. What you should ask when choosing a semiconductor substrate are:

- Can this material distribute and manage heat across its surface?

- How well can the material resist the flow of heat through it?

- If the substrate is a metal bonded ceramic, e.g. DCB Alumina, is there any way to test its overall thermal conductivity?

Ask us for more tips on evaluating thermal properties in substrate materials

Email us at [email protected] or call us on 1-800-292-6286 to discuss your application with our engineering team.