Having instruments that fit perfectly on your bench would be an easy way to achieve just that.

We understand that space and setup can be personal. That's why our RE and REV rotary evaporators offer flexible glassware and bath placement. Position them to the left or right according to what works best for you.

In an industry facing staffing issues, job satisfaction is crucial. Lab techs are grappling with pay, hours, and increasing job demands. Managers are under budget pressure.

Small changes can reduce stress and increase job satisfaction. One way is by having ergonomic essential equipment, like rotary evaporators, that fit perfectly on your lab bench.

Our high-quality construction offers another perk: up to 30% more uptime compared to similar models.

If you're into R&D, this is the go-to instrument for your lab. Dive into the history of rotary evaporation, and you'll see why.

Enhance comfort and productivity in your lab

Rotary evaporators, or rotovaps, have become indispensable in labs worldwide. From the realms of chemical synthesis to crude oil processing, they are versatile powerhouses. But what goes on behind the turning flasks and whirling condensers? Let's delve into the science and history of rotary evaporators to understand how they've revolutionized distillation processes across industries.

The Genesis of the Rotary Evaporator

The rotary evaporator was born out of a necessity to aid chemists and biochemists in their experimental needs. Developed to offer an array of condensers, the equipment serves diverse purposes. Be it fast distillation of mixed solvents, quick sample drying, or chemical synthesis under reflux conditions, rotary evaporators are game-changers in the lab environment. The range of industrial applications is broad, from molecular cooking to extracting natural compounds like cannabinoids.

The Mechanics of Evaporation

At the core of any rotary evaporator lies the principle of evaporation. Defined as the transition of particles from liquid to gas, evaporation kicks in when specific conditions of temperature and pressure are met. Once boiling begins, the liquid experiences a massive expansion, often between 1,000- to 2,000-fold. Therefore, proper distillation equipment is crucial to manage this volumetric increase.

Nucleate Boiling: A Key Step

The initial phase of boiling during distillation is nucleate boiling. Heat triggers gas bubbles enclosed in the container to expand. The resultant buoyancy causes the bubbles to rise to the surface, thereby facilitating better mixing of the liquid. This stage is critical to setting the pace for the rest of the distillation process.

Transferring Heat Efficiently

A vital aspect of boiling is the heat transfer from the source to the liquid. Traditional methods suffer from slow temperature equalization across the liquid layers. Rotary evaporation technology uses constant motion to achieve outstanding heat transfer rates. This speeds up the distillation process by enabling better gas expulsion.

Condensation

If evaporation is the ascending escalator, condensation is the one going down. It reverses the boiling process, requiring cooling to transform the gas back into a liquid state. A well-designed condenser, often vertical or diagonal, ensures that the liquid film formed can flow off easily. The process also dissipates a large amount of pressure, making the condenser act like a pump.

The Role of Vacuum

A vacuum is essential for efficient rotary evaporation as it lowers the boiling points required for distillation. Vacuum sources vary, from laboratory pumps to in-house vacuum lines. The vacuum enables a balanced difference in dynamic pressure, thereby maintaining equilibrium in the heat balance.

Separation Techniques

Distillation serves as a potent separation technique, particularly for liquid mixtures. The method capitalizes on differences in vapor pressures. For substances with close boiling points, fractional distillation becomes the method of choice. It employs a fractionating column filled with glass beads to provide additional surfaces for re-condensation and re-evaporation.

The Best Rotovaps for R&D

If you’re in research and development, you may realize that most rotary evaporators don’t allow you the flexibility to test all your methods.

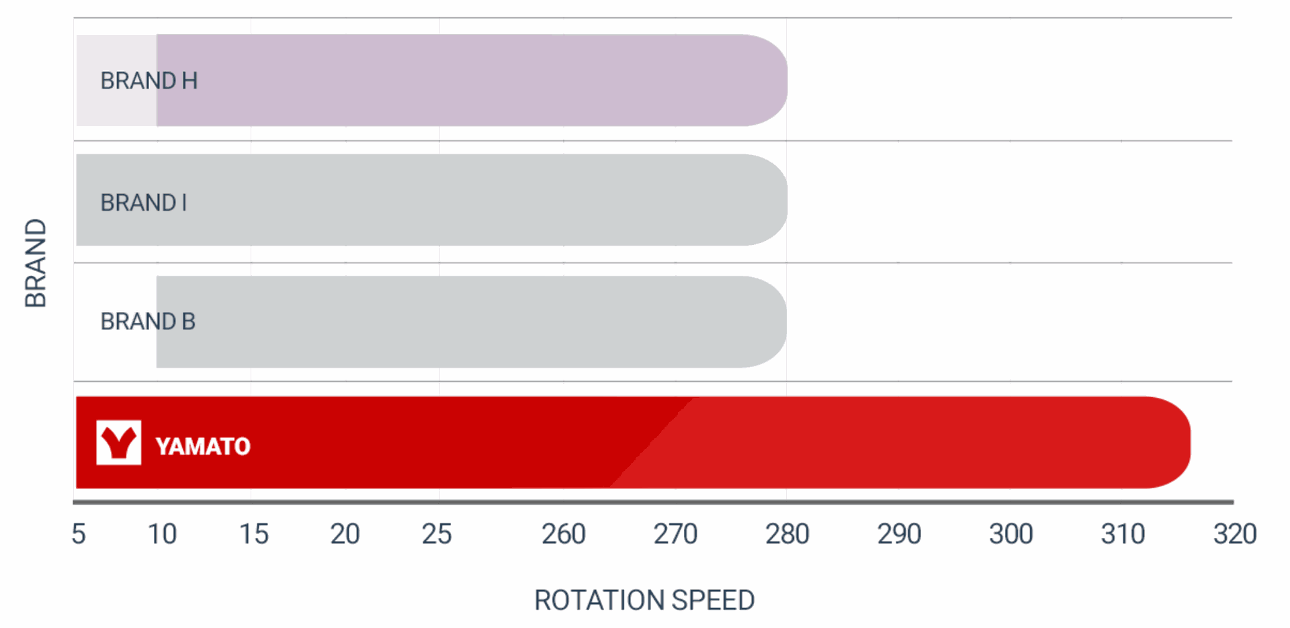

The rotation ranges on Yamato’s mini rotary evaporators range from 5 rpms all the way up to 315 rpms. This is wider than any other on the market, so they’re the most appropriate for QC and testing new SOPs.

With options, our units give you the freedom to optimize your separation and purification processes. Some models even feature a unique "power assist" function, delivering additional torque for faster evaporation rates and reduced processing times.