Is your liquid solution going to work as a powder? Welcome to our crash course on lab‐scale spray drying where we’ll cover the basics, walk you through the main components of a spray dryer, and spotlight the real‐world applications where your competitors and contemporaries are building processes to move their products or research forward.

A quick story about how spray dryer decisions sometimes get made

You’re a busy lab tech, juggling test tubes, running multiple experiments, and suddenly someone in the organization comes up with a bright idea.

“We need a dry powder version of this formulation. We need it yesterday. We’ve promised stakeholders it can be done”

Now you or your team are on the hook for their promise. “Um, sure...?”

That’s where spray drying comes to the rescue.

With spray drying, you take a liquid feed, pump it through a nozzle into a heated chamber, and voilà. Fine, dry particles emerge. It’s efficient, it’s reproducible, and it’s used across industries from pharmaceuticals to materials science.

Why this blog matters to you

For lab technicians

Learn how the process actually works (no more guesswork).

For lab technicians

Learn how the process actually works (no more guesswork).

For managers

Know the equipment and process constraints so you can schedule tasks and manage resources like a boss.

For managers

Know the equipment and process constraints so you can schedule tasks and manage resources like a boss.

For directors

Understand the big‐picture ROI and how to justify investing in quality lab‐scale spray dryers.

If you’re brand new to spray drying, or if you’ve been doing it for years but never dug into the finer details, today’s your lucky day.

You need to have solid fundamentals

From liquid to powder in one step

At its core, spray drying is about transferring heat to rapidly remove moisture from a liquid feed, yielding a dry powder. Here’s the quick breakdown:

- Feed preparation. You make sure your liquid (or slurry) is at the right concentration and consistency.

- Atomization. The liquid is broken into tiny droplets. Think of a really fine mist.

- Hot air & evaporation. These droplets meet hot air inside a chamber. Moisture evaporates in a flash.

- Powder collection. Dried particles drop out of the air stream, usually collected by a cyclone or a simple container.

Why do it this way? Because it’s faster and, generally, gentler on temperature‐sensitive compounds than other drying methods. You get controlled, repeatable results with minimal product handling.

Why lab‐scale spray drying matters

At its core, spray drying is about transferring heat to rapidly remove moisture from a liquid feed, yielding a dry powder. Here’s the quick breakdown:

- Small batches are perfect for R&D where you might only have a few liters of material.

- Process optimization should happen with small volumes of valuable sample. Before you commit to a big production run, it’s wise to test the variables on a smaller scale.

- Cost‐effectiveness can’t be achieved if the potential for waste is as high as with a pilot-scale project. You can, to say it corporately, iterate more quickly, when working with small, more cost-effective batches.

Critical components and technical features you’ll find in your lab scale spray dryer (and differences you’ll see between models as you shop around)

Let’s get to the real hardware behind the magic.

Inlet heater & temperature control

Temperature control can make or break your spray drying run. Why? Because if the inlet temperature is off, you can scorch your product or end up with half‐dried goop.

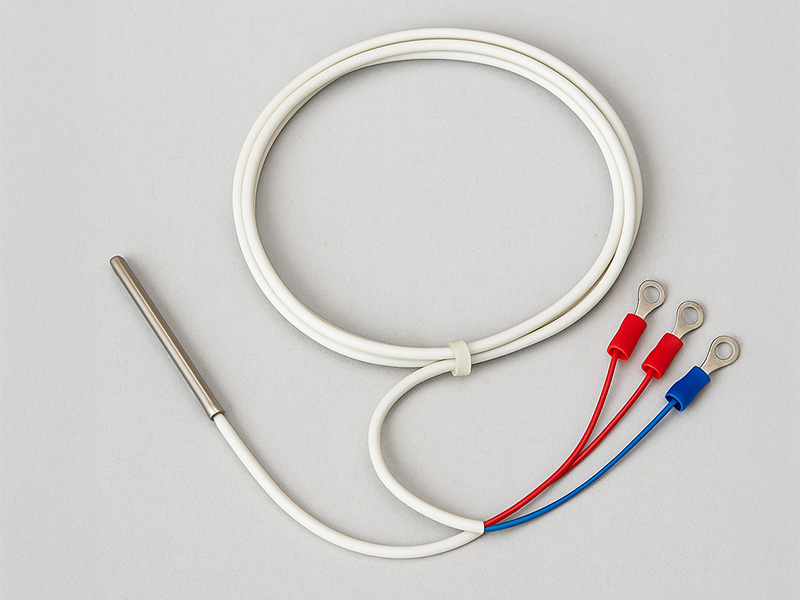

K‐Type Thermocouple:

- Great for higher‐temperature applications.

- Known for faster response time.

- Wide measurement range.

- Very small temperature fluctuation range.

K‐Type Thermocouple:

- Great for higher‐temperature applications.

- Known for faster response time.

- Wide measurement range.

- Very small temperature fluctuation range.

Pt100 Sensor:

- Can be more precise at lower temperature ranges.

- Often used for formulations where temperatures can be forgiving

- Lower cost.

Pt100 Sensor:

- Can be more precise at lower temperature ranges.

- Often used for formulations where temperatures can be forgiving

- Lower cost.

Different feeds call for different temperature setups. For instance, sugary solutions might require lower inlet temperatures to avoid caramelization. A sensor that reacts quickly (like a K‐type thermocouple) could help you stay ahead of those sudden temperature dips or spikes.

Atomization mechanism

This is where your solution turns into a fine mist. Some popular atomization methods include:

Two‐fluid nozzles, using compressed gas and liquid mix to form droplets. It’s easy to adjust droplet size but can clog if you’re not careful.

Two‐fluid nozzles, using compressed gas and liquid mix to form droplets. It’s easy to adjust droplet size but can clog if you’re not careful.

Ultrasonic atomizers, which use high‐frequency vibrations for ultra‐fine droplets. They’re great for sensitive materials, but not the best for thick slurries.

Ultrasonic atomizers, which use high‐frequency vibrations for ultra‐fine droplets. They’re great for sensitive materials, but not the best for thick slurries.

Rotary atomizers are high‐speed spinning discs that fling droplets outward. They’re common in larger production settings.

Drying chamber and cyclone separator

Once the droplets meet hot air, the water evaporates, and the powder forms. A cyclone separator helps swirl out the heavier powder particles from the airstream, depositing them in a collection chamber. The best systems allow easy access for cleaning—especially crucial if you’re switching from one formulation to another and don’t want cross‐contamination.

Feed pump and flow control

If your pump can’t deliver a consistent feed rate, you can kiss consistent particle size goodbye. Some lab spray dryers have peristaltic pumps that let you finely tweak the feed flow. This is super helpful when you’re dealing with multiple formulations, each with its own viscosity and concentration.

Control interface and data logging

A good control panel tells you everything at a glance: current inlet/outlet temperatures, air pressure, and any alarms. Bonus if it logs the data so you can track trends or replicate an experiment a month later.

Where are your colleagues and contemporaries (and enemies!) spray drying

No two labs are exactly alike. But that doesn’t mean you can’t look at how other labs are making good choices with spray drying and apply it to your workplace.

Pharmaceuticals and biotech

- Microencapsulation. Wrapping tiny droplets of active pharmaceutical ingredients in a protective coating.

- Inhalable drug powders. Fine, uniform particles are critical for consistent dosing.

- Heat‐sensitive compounds. Gentle drying in a controlled environment helps maintain compound integrity.

A common scenario…

A biotech lab developing a new inhalable therapy. They choose a Yamato mini spray dryer because they need precise low‐temperature control to avoid damaging protein structures. They also rely on advanced data logging to ensure every test run is traceable.

Food and beverage

- Flavor encapsulation. Think essential oils or flavor extracts turned into stable powders.

- Dairy powder. Milk, whey protein, or even plant‐based milk alternatives.

- Instantizing. Creating powders that reconstitute easily in liquid (like instant coffee).

A common scenario…

A small R&D department at a flavor company is testing a sweet flavor concentrate high in sugar. They keep the inlet temperature a bit lower thanks to a fast‐response K‐type thermocouple so the sugar doesn’t burn. They’re delighted when they end up with a free‐flowing, non‐sticky powder.

Materials science

- Ceramic powders. Creating fine, uniform powders for advanced ceramic parts.

- Nanoparticles. Controlling droplet size can help control particle size at a nanoscale.

- Coatings and pigments. Powdered materials that are easy to blend or disperse in other mediums.

A common scenario…

A research group exploring nano‐scale silica uses a two‐fluid nozzle for ultra‐fine droplets. They appreciate the consistent feed rate so they can collect uniform batches for each trial.

Environmental and chemical testing

- Drying reference standards. A lab might produce small batches of dry chemicals for testing calibration.

- Soil or effluent samples. Drying liquids for easier transportation or longer‐term analysis.

- Extracting volatiles. Some labs carefully control temperature to dry delicate samples without losing key components.

Practical things to think about when setting up your lab spray drying process

The short, short version…

1. Feed preparation and formulation

- Viscosity check. High‐viscosity feeds can clog nozzles.

- Solids content. The more solids you have, the thicker your feed and the more carefully you need to handle it.

- Prefiltration. A quick pass through a filter can remove debris that might block your nozzle.

1. Feed preparation and formulation

- Viscosity check. High‐viscosity feeds can clog nozzles.

- Solids content. The more solids you have, the thicker your feed and the more carefully you need to handle it.

- Prefiltration. A quick pass through a filter can remove debris that might block your nozzle.

2. Optimizing temperatures and airflow

- Inlet temperature. High enough to dry quickly, but not so high that you scorch or degrade your material.

- Outlet temperature. Helps you gauge how fully dry your powder is.

- Airflow. More airflow can mean faster drying, but also smaller droplets might get carried away before fully forming.

2. Optimizing temperatures and airflow

- Inlet temperature. High enough to dry quickly, but not so high that you scorch or degrade your material.

- Outlet temperature. Helps you gauge how fully dry your powder is.

- Airflow. More airflow can mean faster drying, but also smaller droplets might get carried away before fully forming.

3. Sensor choice and control system

- K‐Type vs. Pt100:

- K‐Type if you’re pushing higher temperature boundaries, want a very responsive readout, or control at the outlet (which you should!).

- Pt100 if absolute accuracy at a very specific, established range is your top priority.

- User interface. A simpler interface can reduce training time. Data logging capabilities can be a lifesaver in regulated environments.

4. Equipment footprint and safety

- Ventilation. Some solvents can be flammable or produce fumes. Make sure your hood or exhaust system is adequate.

- Dust hazards. Fine powders can be explosive under certain conditions. Handle them with proper containment.

- Lab space. Even a small lab spray dryer needs enough clearance for safe operation and cleaning.

5. Maintenance and troubleshooting

- Regular cleaning. Residual build‐up can alter your next run’s results.

- Preventive checks. Inspect nozzles, hoses, and sensors regularly.

- Common issues.

- Low yield. Check feed rate, temperature, and nozzle blockage.

- Sticky powder. Lower the inlet temperature or add a drying aid (like maltodextrin in food applications).

1. Feed preparation and formulation

- Viscosity check. High‐viscosity feeds can clog nozzles.

- Solids content. The more solids you have, the thicker your feed and the more carefully you need to handle it.

- Prefiltration. A quick pass through a filter can remove debris that might block your nozzle.

1. Feed preparation and formulation

- Viscosity check. High‐viscosity feeds can clog nozzles.

- Solids content. The more solids you have, the thicker your feed and the more carefully you need to handle it.

- Prefiltration. A quick pass through a filter can remove debris that might block your nozzle.

2. Optimizing temperatures and airflow

- Inlet temperature. High enough to dry quickly, but not so high that you scorch or degrade your material.

- Outlet temperature. Helps you gauge how fully dry your powder is.

- Airflow. More airflow can mean faster drying, but also smaller droplets might get carried away before fully forming.

2. Optimizing temperatures and airflow

- Inlet temperature. High enough to dry quickly, but not so high that you scorch or degrade your material.

- Outlet temperature. Helps you gauge how fully dry your powder is.

- Airflow. More airflow can mean faster drying, but also smaller droplets might get carried away before fully forming.

3. Sensor choice and control system

- K‐Type vs. Pt100:

- K‐Type if you’re pushing higher temperature boundaries, want a very responsive readout, or control at the outlet (which you should!).

- Pt100 if absolute accuracy at a very specific, established range is your top priority.

- User interface. A simpler interface can reduce training time. Data logging capabilities can be a lifesaver in regulated environments.

4. Equipment footprint and safety

- Ventilation. Some solvents can be flammable or produce fumes. Make sure your hood or exhaust system is adequate.

- Dust hazards. Fine powders can be explosive under certain conditions. Handle them with proper containment.

- Lab space. Even a small lab spray dryer needs enough clearance for safe operation and cleaning.

5. Maintenance and troubleshooting

- Regular cleaning. Residual build‐up can alter your next run’s results.

- Preventive checks. Inspect nozzles, hoses, and sensors regularly.

- Common issues.

- Low yield. Check feed rate, temperature, and nozzle blockage.

- Sticky powder. Lower the inlet temperature or add a drying aid (like maltodextrin in food applications).

How can you achieve your spray dryer goals (based on your role in the lab)?

Lab technicians - Just tell me how to run it!

- Create a parameter sheet for each formulation (feed concentration, inlet/outlet temps, flow rate).

- Check the nozzle regularly - clogs happen when you least expect them.

- Keep a cleaning log, especially if you switch formulations often.

Managers - I need to keep everyone happy and on budget.

- Look for consistent run times and stable throughput so you can schedule tasks efficiently.

- Prioritize reliable components to reduce downtime (hello, accurate sensors and robust feed pumps).

- If your lab is doing a lot of different experiments, a user‐friendly interface will save you from constant “tech help” calls.

Directors - Show me the ROI.

- Accurate equipment = fewer failed batches. Less material wasted.

- Process scalability. Good data at the lab scale sets the stage for pilot or production scale.

- A versatile spray dryer can be shared among departments, maximizing investment.

So what does this all mean for you today?

Spray drying in the lab is all about precision, consistency, and flexibility. A good lab spray dryer lets you dial in the exact temperatures, flow rates, and atomization methods you need, whether it’s a delicate biological compound or a sticky flavor formulation.

Your key takeaways are…

- Understand why temperature control (and the right sensor) matters.

- Know your feed properties (viscosity, solids content) to avoid clogging nightmares.

- Use a system that offers accurate, responsive controls to save time (and headaches).

- Different industries have different goals but the same need for reproducible results.

In our next spray drying blog…

We’ll be exploring best practices for optimizing your spray drying process in our next blog. Things like temperature fine‐tuning, preventing stickiness, and general troubleshooting tips.