Essential to weighing applications of powdered samples, chemical, and biological products, a Vented Balance Enclosure (VBE), also referred to as a Ventilated Balance Enclosure, is one of the most important tools a lab should capitalize on to prevent exposure accidents.

With high airborne contamination risks from closely monitoring and weighing active drugs or harmful compounds, getting the right VBE for your facility secures not just worker- and environment-safety but also weighing measurement accuracy.

Unlike traditional fume hoods that are built to only contain and safeguard users from hazardous fumes or vapors, VBEs are more effective when it comes to handling and measuring fine toxic powders. Compared to chemical fume hoods, these come with a filtration system to ensure both user and workroom protection from particulate contamination. And since VBEs present lower ventilation rates and lesser balance disturbances in comparison with fume hoods, these are highly recommended for accurate and precise weighing applications in pharmaceutical, chemical, and biotechnology laboratories to name a few.

Investing on VBEs that would guarantee personnel protection and optimal balance performance would require a budget so finding one that would last you long should be one of your goals. With a plethora of vented balance enclosures available at different price points in the market, how do you find the best-suited model for your applications? Yamato Scientific America has prepared this quick and easy guide with a list of questions, features, and tips to consider before making that VBE purchase. Don’t waste budget on the wrong model to avoid costly mistakes. Shop smart by reading this guide first before ordering a unit today.

Key Questions to Answer Before Scouting Vented Balance Enclosures

1. What materials will you be working on?

Take down notes on the samples you will be handling. Indicate if these are active pharmaceutical ingredients, chemicals with high toxicity at low levels of exposure, or strong compounds. Review safety information of these materials as it can help you trim down options in the long run, only considering VBE models that can meet hazards of the samples you will be working on. With these data listed, you can also ask help from manufacturers to point you to the right enclosure.

2. What are your area and size requirements?

A vented balance enclosure may have all the top-of-the-line features but it would not be the perfect unit for you if you can’t properly fit it in your facility. Before purchasing one, be sure to check the free space you have in your workroom first, considering it before deciding on the VBE model to get. Take note of inner and outer dimensions when browsing for models.

Vented balance enclosures are smaller in size compared to traditional laboratory fume hoods as these are particularly designed for weighing procedures. Most models would only range from two to five feet in width, just like the Yamato Vented Balance Enclosures. When you have finalized your dimension requirements but model specifications are not listed on manufacturer websites, you can always ask them for recommendations based on your size preferences.

3. What is your working budget?

If you are tight on budget, it would be ideal to get a smaller balance enclosure that would recirculate filtered air into the lab. This way, it would only occupy a smaller lab space, use less energy, and require lower installation costs since no ducting set-up is needed.

When scouting for VBE models, you should also bear in mind certification and maintenance costs. In order to ensure the unit is working up to standards, it should be certified at least every year, whenever the VBE is serviced, or when filters are replaced. Maintaining a VBE not only involves replacing or testing filters but also cleaning the unit on a daily or weekly basis, so expenses on disinfectants or cleaners should be added to the equation as well.

4. What filtration type do you need?

Filter requirements would depend on your applications and the size of particles you want filtered out. You would also need to assess if you want these filtration systems to be mounted on top of the VBE like the Yamato models or have it external to it and connected to an exhaust, as well as if you want filtered air to recirculate back in your lab or outside of your facility. All these choices would affect costs and energy savings you’ll get from the unit.

Download How to Purchase the Right Vented Balance Enclosure Guide here

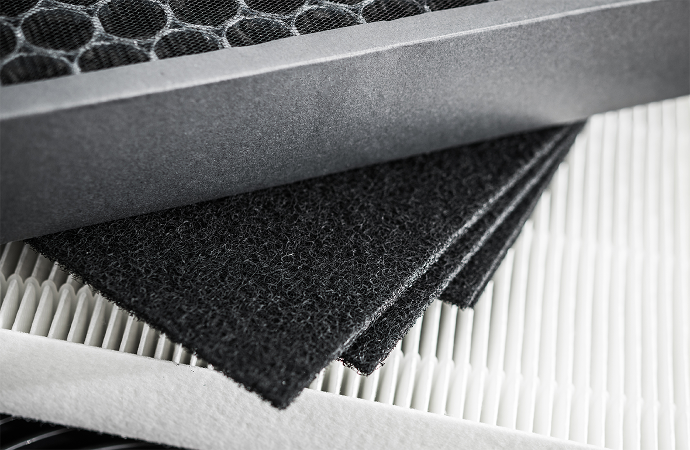

HEPA Filters

The most common type of filtration vented balance enclosures come with is High Efficiency Particulate Air (HEPA) filtration. These disposable HEPA filters are made of glass microfibers packed into flat sheets, capable of trapping airborne particles, microorganisms, or particulate contaminants 0.3 micron (μm) in diameter.

Depending on what applications are done with the VBE, how long the VBE is used, and the air quality in the lab, HEPA filters may last for three to five years before replacement. If you’re leaning towards VBEs that use HEPA filters, best to consider the Yamato Vented Balance Enclosures.

Carbon Filters

The carbon filters trap odors from chemicals being worked on including organic vapors and solvents, ammonia, sulfur and nitrogen compounds, and more. Some VBEs use a combination of both carbon and HEPA filters, therefore catching toxic particulates as well as gaseous contaminants. If you wish to add carbon filters, aside from existing HEPA filters, on Yamato Vented Balance Enclosures, this can be done as a customization.

ULPA Filters

If you will be working on specialized applications and would need to capture particles with dimensions ranging from one to 100 nanometers, then it is best to go for balance enclosures offering Ultra Low Penetration Air (ULPA) filters. ULPA filters are able to catch 0.12 micron (μm) particles and nanoparticles that may pose serious health risks. Yamato is also able to replace HEPA filters with ULPA filters as a customization.

Features to Look Out for in Vented Balance Enclosures

1. Effective Filtration System

If you often deal with particulate matter toxic at low levels of exposure, you do not want to be staying long in a lab circulating poor quality or possibly harmful air. Vented balance enclosures with high-efficiency filtration systems should be a top priority.

2. Robust Construction

Go for VBEs that would not only guarantee safety, user convenience, and improved productivity but would also last you long. The amount you will be paying for a unit is not cheap so you better get your money’s worth.

Make sure the models you are eyeing on are heavy-duty and are made from quality materials.

Consider Yamato Vented Balance Enclosures constructed with optically clear ⅜” jeweled acrylic plastic for hassle-free viewing of samples. These VBEs present higher analytical balance stabilization thanks to its phenolic base known for its superior chemical resistance. Since the base is black, easy powder detection is assured as well.

Prioritizing worker protection, these Yamato VBEs also feature a front viewing sash complete with multiple airfoils and an adjustable front draft for higher containment of fine powders, chemicals, and biological products understudy.

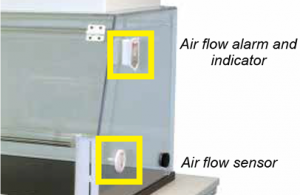

3. Reliable Alarm Systems

Lean towards balance enclosures with airflow and face velocity alarm systems for additional laboratory researcher protection. Yamato Vented Balance Enclosures deliver next generation alarm technology, showcasing audible and visual alarm functions to track air velocities within the balance enclosure.

4. Optional Features

Other features for additional safety measures to take note of include a bag-in / bag-out port for safe filter disposal or changeouts, an electrical cord outlet port, and a canopy connection if you want the VBE to be connected outside your cleanroom.

Vented Balance Enclosure Installation Tips from the Experts

1. Avoid placing vented balance enclosures on areas with equipment or furniture that might produce vibrations, like mobile carts or wobbly tables, as these would affect balance

performance. Vibration transmissions can be greatly minimized by securely attaching the chamber to the floor or the wall.

2. Don’t position vented balance enclosures near high traffic areas, open doors and windows, or spaces close to ventilation systems such as fans, heaters, or air conditioners. This is because obstructed airflow patterns, air brought about by moving doors or people passing by, and unnecessary air currents can all impact a balance’s weighing results.

3. It is best to install vented balance enclosures in rooms where temperature is regulated, away from spaces exposed to direct sunlight, incandescent lights, and other heat sources. When sample and room temperatures are kept nearly equal, possibilities of samples expanding due to high temperature or contracting due to low temperature are avoided, therefore securing a balance’s measurement accuracy.

Consider Only the Best and Get Your Money’s Worth.

Yamato Scientific America offers a new line of heavy-duty vented balance enclosures best-suited for weighing applications in pharmaceutical, biological, biotechnology, and chemical laboratories. Backed with over 130 years of experience in the scientific industry, trust Yamato Scientific America to offer only top quality VBEs that make way for optimal balance performance and worker safety as well as ensure long operational life.

Find the VBE your application exactly requires by checking out Yamato’s latest models — all manufactured under strict quality control settings and in compliance with international standards. We can also modify and customize the equipment to meet diverse applications and requirements. Tell us what you need, we will try to make it happen.

For more information on our available vented balance enclosures, visit Yamato Scientific America at www.yamato-usa.com or contact us at 1-800-292-6286. You can also email our customer service support at [email protected].

Download How to Purchase the Right Vented Balance Enclosure Guide here