Turn hours into seconds

Imagine what you could do with a few extra hours in your lab. More research, enhanced quality assurance, or even some well-deserved rest, perhaps? Hold that thought, because we're about to reveal how Yamato spray dryers can revolutionize your powder production process, making it quicker and more efficient than ever.

While freeze-drying, lyophilization, is excellent for preserving the quality of sensitive materials, it might not be the most cost-effective or quickest method for all applications. Here's an overview of the general process:

Pretreatment: This step may involve adjusting the pH, adding preservatives, or applying other treatments to the material to prepare it for freeze-drying.

Freezing: The material is frozen, usually in a special freeze-drying chamber. The freezing process converts the water content in the material to ice.

Primary Drying (Sublimation): Under vacuum conditions, the frozen material undergoes sublimation, which is the direct conversion of ice to vapor, skipping the liquid phase. This is done at low temperatures to ensure that the structure and composition of the material are not compromised.

Secondary Drying (Desorption): The material undergoes further drying to remove any remaining water molecules that are bound to the material. This is usually achieved by slightly increasing the temperature while maintaining the vacuum.

Freeze-drying is generally a slow process, which can take anywhere from hours to days to complete. This drying method also requires a substantial amount of energy, particularly because of the vacuum and low-temperature conditions, making it more expensive in terms of operational costs.

Seamless drying in a flash

Spray drying has been a go-to solution in the food and beverage industry for over a century, but its remarkable efficiency makes it a strong candidate for other sectors as well. Before diving into the efficiency metrics, let's take a step back to understand what spray drying is. Spray drying is a method used to produce dry powders from a liquid or slurry by rapidly evaporating the solvent. The technique employs a spray nozzle to atomize the liquid into fine droplets, which are then exposed to hot air, facilitating rapid evaporation and leaving behind a dry powder.

From liquid to powder in one-step

In a typical spray drying system, the core components include a feed pump, an atomizer, a drying chamber, and a collection system. The process involves these key steps:

Atomization: The liquid feed is atomized into small droplets using a rotary or nozzle atomizer.

Mixing with hot air: These droplets are mixed with hot air in a drying chamber, allowing for quick evaporation of the solvent.

Drying: The process takes place in milliseconds to seconds, transforming the droplets into dry powder.

Separation: The powder is then separated from the hot gasses using cyclones or bag filters.

Benefits of air-drying over traditional methods

Unlike vacuum oven drying, spray drying ensures uniform particle size and moisture content. The rapid drying phase in a spray dryer also prevents degradation of heat-sensitive materials, unlike vacuum ovens.

✅ Short exposure to hot air to maintain sample quality.

✅ No contact with surfaces to minimize contamination risks.

✅ Rapid drying in mid-air to ensure no uneven particle sizes.

✅ Elimination of extra steps to simplify your workflow.

Relevance to other industries

For the pharmaceutical industry, spray drying is critical for producing consistent, high-quality active pharmaceutical ingredients (APIs) and excipients. In the chemical industry, it aids in manufacturing various products like dyes, detergents, and catalysts with high purity and homogeneity. For inorganic material production, spray drying can be used for producing ceramic powders, metal oxides, and composite materials.

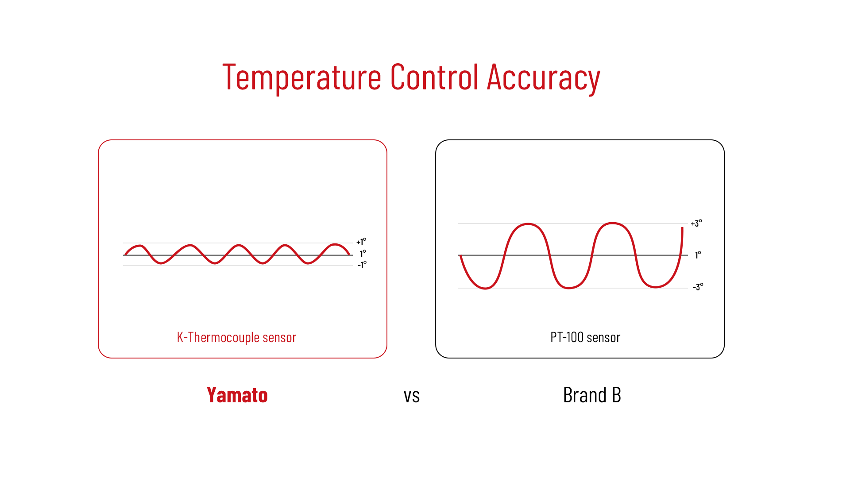

K-Thermocouple Sensor

What sets Yamato apart is its state-of-the-art K-Thermocouple sensor, allowing for temperature control that’s more accurate and stable than brands using a PT-100 sensor. This ensures your drying process is not just fast but also incredibly reliable.

Scalability meets cost-effectiveness: stay ahead in the powder game

One of the key advantages of spray drying is its scalability and suitability for both batch and continuous production processes. This flexibility allows organizations to adapt their spray drying operations according to their production needs, be it in a lab for R&D or in a large-scale manufacturing facility. Whether you're developing a new formulation in a lab or aiming for high-volume production, spray drying offers an efficient, scalable, and reliable path. With advances in technology, including precise control systems and sensor technologies, spray drying will continue to be a cornerstone in industries ranging from food and pharmaceuticals to chemicals and advanced materials.

Ready for a faster, more efficient drying process?

Our team is more than ready to walk you through the ins and outs of spray drying and help you determine if it's the right fit for your lab operations.